Heat pumps: how do they work and how to maintain them?

Heat pumps are the new stars of the heating world. These systems outperform others on several fronts, and many governments are introducing new laws and regulations to encourage their use, not least because they’re better for the environment and help combat climate change. In this article, we take a detailed look at the nuts and bolts of this technology.

Why install a heat pump?

-

Because fossil fuels are falling out of favour:

Climate and environmental concerns are prompting many governments, especially in Europe, to encourage a shift away from gas and oil-fired boilers and towards heat pumps, which run on electricity. The aim behind such policies is to cut CO2 emissions and to reduce dependency on gas, the price of which is subject to fluctuations – often upwards. In France, for example, new rules mean that heat pumps are preferred to combustion boilers in individual new-build homes from summer 2021. -

Because heat pumps are extremely efficient:

Heat pumps offer greater energy efficiency than even the best condensing boilers. And although they perform significantly worse when the outside temperature drops below -7°C, there are some clever installation tricks to help get around this problem in colder climates. -

Because the technology is proven and robust:

Heat pumps work in exactly the same way as air-conditioning units and fridges. This means they’re backed by tried-and-tested technology that’s been improved over time, with little to be concerned about in terms of maintenance. -

Because they’re extremely versatile when it comes to installation:

The sheer range of heat pump set-ups makes them suitable for installation in all types of building and environments. For instance, it’s possible to replace a combustion boiler with a heat pump while keeping the domestic heating water circuit installed. And they can even be used to heat a swimming pool! -

Because some governments offer financial incentives:

In some countries, governments offer home-owners financial support towards the cost of converting from a gas and oil-fired system to a heat pump. In some cases, the packages available are extremely generous, covering a large portion of the installation cost.

How does a heat pump work?

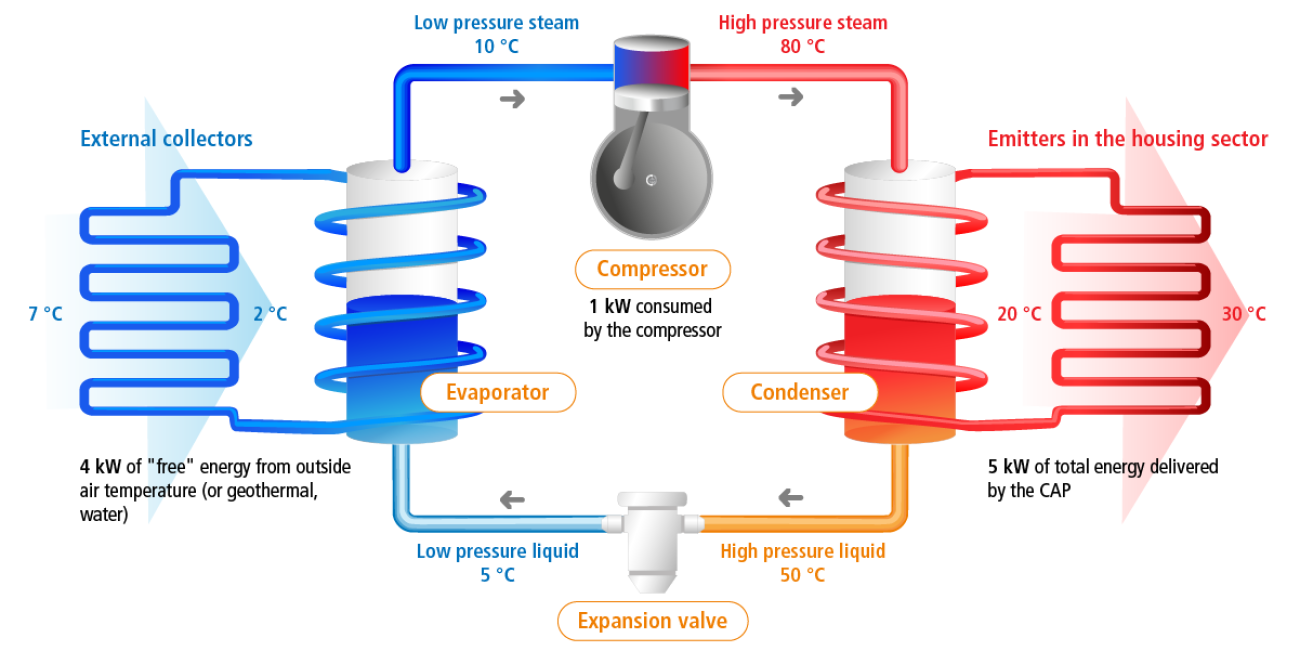

Temperatures and wattages mentioned in this diagram are indicative, they may vary.

A heat pump brings warmth from outside a building indoors. At the heart of the system is a refrigerant circuit that transports heat (thermal energy) through a process of state change:

-

Step 1: Outside the building, the evaporator collects ambient heat, which warms the fluid in the circuit. This exists at an extremely low temperature and consists largely of a low-pressure liquid. Under the effect of the heat, the liquid turns to gas. This gas is then compressed rapidly in a compressor, which dramatically raises its temperature.

-

Step 2: Inside the building, the hot gas enters a condenser, where it heats water or air. This is then used to heat the property. This process cools the fluid once again, which condenses and returns to its (almost) liquid state. The fluid then passes through an expansion valve, where the sudden pressure drop causes a sharp reduction in temperature – and the cycle starts again at step 1!

In other words, a heat pump works in exactly the same way as an air-conditioning unit, except the entire process operates in reverse. That’s why it’s possible to fit a reversible heat pump system (known as an “inverter”), which keeps a building cool in summer and warm in winter. In summer, the outdoor part of the system functions as a condenser and the indoor part as an evaporator.

For this reason, it’s important to choose the right heat pump set-up from the outset:

-

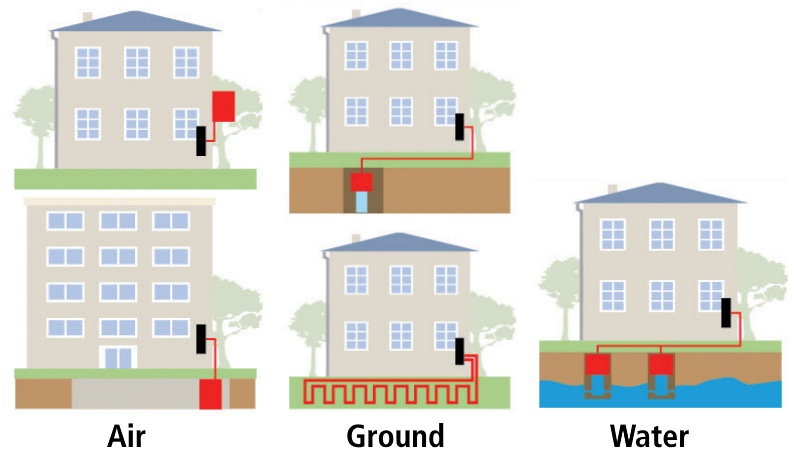

Air-to-water heat pump: this system features an outdoor unit that heats the fluid by blowing ambient air. The system feeds into a conventional water-based heating circuit (radiators or under-floor heating) and also provides domestic hot water.

-

Water-to-water heat pump: with this set-up, the refrigerant is heated passively as it passes through a naturally occurring body of water such as the groundwater table or a lake or river. This system is more energy-efficient and is better suited to places that experience bitterly cold winters.

-

Air-to-air (or water-to-air) heat pump: this is a “split” type system that uses warm air to heat a property. Its main advantage is that it can be reversed – in other words, it can serve as an air-conditioning system using exactly the same equipment.

Since heat pumps absorb heat from outdoor air, their performance drops significantly in colder climates. Below -7°C, the system requires much more energy to extract warmth from the cold air and heat the refrigerant in the evaporator. One handy tip is to situate the air inlet at some distance from the evaporator and connect the two with a long buried pipe. With this set-up, known as a ground-coupled heat exchanger, geothermal heat warms the air naturally as it moves underground before reaching the evaporator.

The main measure of a heat pump’s efficiency is its Coefficient of Performance (COP). For example, a COP value of 3 means that the system delivers 3kW of heat output for every 1kW of electricity used to run the pump. Effectively, this means you get 2kW of “free” energy by absorbing heat from outdoors. So it’s easy to see why the external temperature makes such a big difference to a pump’s COP value!

Note that our Si-RM350 and Si-RM450 manifolds can also calculate EER, another similar index that describes the ratio between actual cooling capacity (in BTUs) and energy consumption (in Watts): an EER of 10 means that for every 1 Wh consumed, the system produces 10 BTU/h.

Other, more specific efficiency indices also exist to provide a less theoretical assessment of performance: SCOP (Seasonal Coefficient of Performance) and SEER (Seasonal Energy Efficiency Ratio). These two indicators are more realistic, as they take into account several reference outdoor temperatures in a given season:

SCOP (Seasonal Coefficient of Performance):

-

Operating mode: Heating

-

Measurement period: Entire heating season

-

Calculation: Total quantity of heat produced over a season / Total quantity of energy consumed over the same period.

-

Technical details:

- Reference temperatures: SCOP is calculated using four predefined operating points: -7°C, +2°C, +7°C, and +12°C

- Reference climates: Three European climates are used for the calculation: warm climate (Athens), temperate climate (Strasbourg), and cold climate (Helsinki).

- European standard: SCOP is defined according to the ErP (Energy-related Products) standard, which takes into account the appliance's seasonal performance.

SEER (Seasonal Energy Efficiency Ratio) or “seasonal cooling efficiency”:

-

Operating mode: Cooling

-

Measurement period: Entire cooling season

-

Calculation: Total quantity of cooling provided over a season / Total quantity of energy consumed over the same period

-

Technical details:

- Reference temperatures: SEER is calculated using average outdoor temperatures between 13°C and 46°C.

- Measurement conditions: SEER takes into account outdoor temperature variations during the cooling season, assuming a constant indoor temperature of 20°C and a reference outdoor temperature depending on the region concerned.

- Energy label: Air-conditioning and air-to-air heat pump units display SEER on their energy label, enabling consumers to easily compare energy performances.

Servicing heat pumps: what does it involve?

Reliability is one of the big advantages of heat pumps. The refrigerant is designed to last forever, provided there are no leaks – which are rare. Think of a heat pump like a fridge, which can run for many years without ever needing to be maintained. However, some countries like France now require heat pumps to be serviced every two years, and every year for high-powered systems. For engineers, this means inspecting various aspects of the system in order of priority using a manifold – the most important tool required for this kind of work, and already widely used for air conditioning systems.

-

Detect refrigerant leaks:When this issue does occur, it will put the entire system out of operation. Our Si-RD3 refrigerant gas detector is the ideal tool for the job. If you detect a leak, you’ll need to drain the circuit, repair it, and then use a vacuum probe (Si-RV3 or Si-RV4) to make sure the circuit is leak-tight.

-

Measure high side and low side pressure:

Another indicator of a leak is when the difference (Delta) between the high side (superheat) and low side (subcooling) pressure is too small. But most importantly, measuring these parameters will tell you whether the heat pump is performing efficiently, and whether the compressor and expansion valve are working properly. You’ll need a digital manometer, like our Si-RM350, Si-RM450, Si-RM3 or Si-RM13 manifolds, to take both of these measurements simultaneously.

-

Measure superheat and sub-cooling:

Accurately read these two parameters by placing a thermocouple thermometer like our brand-new Si-TT3 model directly on the copper refrigerant pipe. That way, you’ll be able to measure the superheat temperature at the compressor outlet and the sub-cooling temperature at the expansion valve outlet. Both values should be consistent with the thermal state-change properties of the refrigerant inside the circuit. If this is the case, you’ll know that the heat pump is operating correctly (too high a superheat may indicate a lack of fluid, too low a subcooling may indicate a fluid overload or a condenser problem). Our digital manifolds come with built-in thermometers with high speed CTN sensor, allowing you take temperature and pressure readings at the same time. Meanwhile, our app automatically checks the readings against the correct values for more than 130 different refrigerants, based on the pre-populated thermal properties stored in the database.

-

Replace the refrigerant:

Sometimes, you might need to replace the refrigerant in the circuit to bring the heat pump up to standard or to improve its performance. You’ll need to recover all the fluid so it can be recycled, and make sure the circuit is completely empty once you’ve finished. This operation also requires a vacuum probe. You’ll find one built into our Si-RM3, Si-RM13, Si-RM350 and Si-RM450 manifolds, which are also useful for other commissioning tasks. -

Commission the heat pump and fill the circuit with fluid:

If you’re installing a new heat pump, or commissioning the system after fixing a leak or replacing the fluid, you’ll need to use a manifold to take vacuum, pressure and temperature readings once you’ve filled the circuit. Simultaneous high-pressure/low-pressure and temperature measurements enable rapid circuit diagnostics, to check that the load is correct, which determines the system's efficiency.

-

Inspect and clean the thermodynamic system:

Servicing requirements extend beyond the core heat pump itself. For water-based heating systems, you’ll also need to check that various other components are in working order, including the hot water tank, the heating system water pumps, the compressor, the expansion valve and the electrical parts. An infrared thermometer, like our Si-TI3 model, can be used to detect abnormally high temperatures in electrical systems. And for reversible heat pumps, you’ll also need to make sure that the condensate removal pumps are in good working order – and, if necessary, clean them (see our cleaning guide) or replace them (see our mini condensate removal pumps for air conditioning units). For reversible heat pumps, you should also check that the condensate pumps are working properly, cleaning or replacing them if necessary.More information on condensate pumps:

-

Air flow rates to outdoor and indoor units:

The final – and easiest – thing to check is that the fan units are working properly. You can do this by measuring the air flow rates using a vane thermo-anemometer like our Si-VV3 model. You might need to repair the fan or clean out things like leaves, moss or dust to restore the evaporators and condensers to full working efficiency – and to reduce noise during operation.

If you’d like to know more about which tools you need to service a heat pump, take a look at our comprehensive product range, which includes all the measurement instruments and condensate removal pumps required for this type of task.

Add new comment