Recycling condensates from heating and air conditioning systems

Gas-fired boilers, air conditioning units and tumble dryers all produce water through a natural process known as condensation. Our condensate removal pumps are specially designed to capture this excess liquid, which can then be retrieved and reused as a way to save tap water.

But recycling this water requires a good dose of caution, because some condensates are acidic. Here’s our comprehensive guide to help you avoid any nasty surprises.

Which condensates are acidic, and why?

Only condensates produced by fuel-burning heating systems are acidic. This acidity is caused by a series of chemical reactions that occur during the combustion cycle.

-

Combustion produces carbon dioxide (CO2), which forms carbonic acid (H2CO3) when it comes into contact with the condensates generated by the boiler:

CO2 + H2O => H2CO3 -

Some fossil fuels (such as coal and heating oil) contain impurities, which also release small amounts of sulphur dioxide (SO2) when burned. When sulphur dioxide dissolves in water (condensates), it produces sulphuric acid (H2SO4):

SO2 + 2H2O => H2SO4 + H2 -

Old boilers, or systems that burn fuel inefficiently, will also produce nitrogen oxides (NOx). Nitrogen dioxide (NO2), which is one kind of nitrogen oxide, reacts with water (condensates) to produce nitric acid (HNO3):

3NO2 + H2O => 2HNO3 + NO

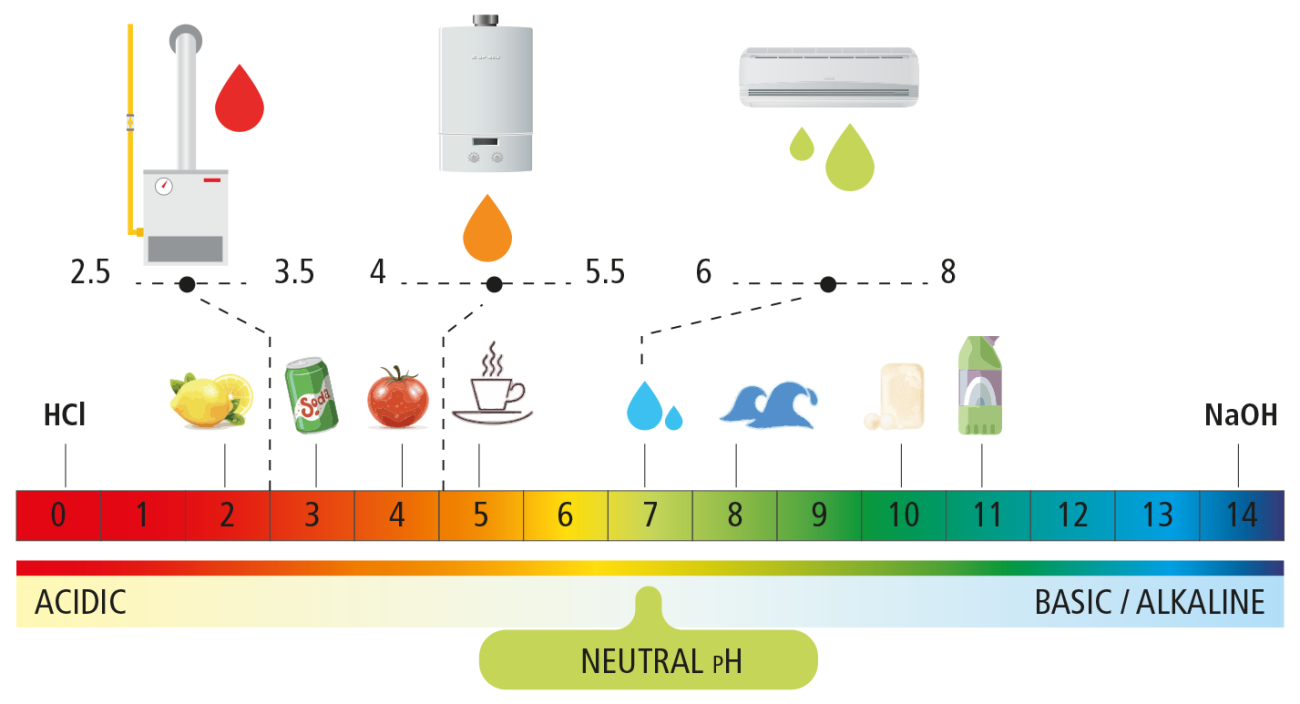

As a general rule, most gas-fired boilers only produce carbonic acid, meaning the condensates they release are moderately acidic (pH 5 on average). Only the very oldest gas-fired boilers, or boilers that haven’t been properly configured using a combustion gas analyser, will generate condensates containing nitric acid. These condensates are more acidic (approx. pH 4).

Boilers that burn fossil fuels (such as coal or heating oil) produce condensates that are much more acidic because they also contain sulphuric acid. Even in small amounts, this compound can lower the pH value to around 3.

In most cases, the condensates produced by air conditioning and refrigeration systems (and by tumble dryers) are pH-neutral. Because air conditioning condensates contain only tiny amounts of dissolved CO2, they’re similar in pH value to rain water or distilled water. Moreover, they aren’t exposed to sulphur or nitrogen oxides, and contain no minerals. Scientific studies have shown that condensates generated by air conditioning units have a pH value of between 6 and 8, even in polluted urban environments. Since a pH value of 7 is neutral, these condensates can sometimes range from slightly acidic (pH 6 to 6.9) to slightly alkaline (pH 7.1 to 8).

Why are acidic condensates problematic?

Acidity causes a major problem: corrosion. Condensates from combustion boilers therefore need to be handled with care, since they can corrode metal pipes (coppers, cast iron, etc.) and potentially weaken the concrete foundations beneath homes. The effect happens slowly, over a period of several years, and has even caused buildings to collapse in the past.

These days, condensates are channelled through PVC pipes, or pipes made from more expensive stainless steel (the only metal that is entirely resistant to corrosion). That’s also why flue gas pipes are always made from stainless steel: when condensation happens inside the pipe, the water comes into contact with high concentrations of CO2, sulphur and nitrogen in the gas, turning it acidic.

In older buildings where replacing existing metal pipes isn’t possible, the only option is to install a neutralisation cartridge to reduce the acidity of the condensates generated by the boiler and to bring the pH value up to around 7. The best cartridges typically last for several years, although their lifespan depends on how much condensate the boiler produces and how acidic it is.

That’s also why condensate removal pumps for boilers are built to withstand corrosion: every component that comes into contact with condensates is made from stainless steel or PVC. A simple but effective solution!

It’s also a bad idea to dispose of acidic condensates in a septic tank because the acid will kill the bacteria that keep the system self-regulating. Pouring acidic condensates down the drain and into the sewer is less problematic: the condensates will dilute and become less acidic when they mix with other liquids, especially if they contain soap and detergent (which are alkaline, i.e. they have a pH value well above 7). Nevertheless, it’s generally advised to protect some types of sewer with a neutralisation cartridge (although there’s no legal requirement for households to do so).

What else do condensates contain?

It’s common to find lots of other particles and substances in acidic condensates produced by combustion boilers. If the boiler burns fuel inefficiently, the condensates might contain combustion residues. These can include hydrocarbons absorbed from the flue gases, as well as volatile organic compounds (VOCs), soot and other dirt residues. In some cases, acidic condensates can also contain corrosion by-products such as oxidised metal and rust, and even flecks of acid-damaged concrete.

While the condensates produced by air conditioning units aren’t acidic, they can still be contaminated with dust and other forms of indoor air pollution. In this case, location is the decisive factor. A unit in a hair salon will release condensates loaded with hairspray particles, which can stick to pipes and even cause blockages. In kitchens, the condensates will contain cooking oils and fats, which also cause headaches when they build up. And the examples go on: flour in bakeries, cellulose particles in paper mills, or cigarette smoke in smoking rooms.

But there’s one problem that tops the rest when it comes to air conditioning and refrigeration condensates: biofilm. This thick substance, which forms inside drain pipes, is caused when bacteria accumulate and build a “cocoon” to create the environmental conditions they need to multiply. Biologically speaking, biofilm isn’t especially hazardous. But from a maintenance perspective, it can be a real nightmare – especially in supermarket refrigerated display cabinets and similar systems, where it can block drain pipes and cause leaks. The only answer is to take effective precautions.

For further reading, we discuss the issue of biofilm and air conditioning units in these two INsights blog articles:

- [How to] How and why should you clean the condensate removal pump in your air conditioning unit?

- Si-1931 + Gel-clear tablet: five reasons to prevent the formation of biofilm in supermarket aisles

How much condensate can a system produce?

It’s important not to underestimate the amount of condensate that boilers and cooling systems (air conditioning units, fridges and freezers) can produce. In fact, to the uninitiated, the figures might come as a shock!

Each hour, a combustion boiler will release around 0.14 litres of condensate per kW of power. That means that a relatively modest 10 kW residential boiler will produce around 1.4 litres of condensate an hour when running at full power – and 33 litres a day if it operates around the clock. In winter, running at full power for an average of six hours a day, the boiler will generate almost 60 litres a week. And over the course of a year, operating for an average of 1,500 hours, a 24 kW boiler could release a staggering 5,000 litres of condensate!

The figures for air conditioning systems are even higher: depending on relative humidity, a unit will normally generate between 0.5 and 0.8 litres of condensate per hour per kW of power. To be on the safe side, many engineers work on the basis of 1 litre per hour per kW of cooling power. An air conditioning system in a typical 100-square-metre property will therefore produce somewhere in the region of 20-40 litres of condensate per day. The only way to calculate a more exact figure is to measure relative humidity, temperature, absolute pressure, the total volume of the room, the exact power of the unit, and the air flow through the system (using an anemometer or an air flow meter).

As a ballpark figure, if you use an air conditioning system to cool your home in summer, you can expect it to produce around 600 litres of pure, pH-neutral condensate per month. That’s a lot of water, especially if there’s a drought!

How do you recycle boiler condensates?

Recycling boiler condensates isn’t easy because they’re acidic and contain residues. The condensates produced by boilers that burn fossil fuels (such as coal and heating oil) are of limited use as they contain such high levels of impurities.

For simplicity’s sake, it’s better to focus on from modern gas-fired condensing boilers, which are cleaner and less acidic (pH 5 on average). Neutralising these condensates is generally recommended, although it isn’t always necessary since some plants prefer slightly acidic soil. Examples include ferns, irises, camelias, blueberry bushes and orchids, along with many other flowering plants, perennials, fruits and vegetables. It can also be helpful to mix condensates with rainwater – either naturally or deliberately – to reduce the acidity to a safe level. It’s also worth remembering that plants need nitrogen – found in boiler condensates in the form of nitric acid – to support photosynthesis.

Boiler condensates shouldn’t really be used for anything other than watering the garden because of the impurities they can contain. It’s possible to recover the heat from condensates (which are typically at 30-80°C) – modern boilers already do this internally. Some high-end industrial boilers even recover hot condensates and re-inject them into the system through the water inlet, saving a considerable amount of energy. But of course, that’s only possible if all the pipe work is made from stainless steel!

How do you reuse condensates from an air conditioning unit (or a tumble dryer)?

Because air conditioning units produce pH-neutral condensates that are much cleaner than boiler equivalents, there’s much broader scope for reusing them. As for tumble dryers, the condensates they generate are just as pure and pH-neutral but can sometimes contain textile fibres. However, modern tumble dryers are fitted with a heat pump and a small condensate removal pump (not the same as our mini condensate removal pumps) to channel excess water into a tray at the top of the appliance. These condensates tend to be extremely clean, containing no textile fibres. Here are our tips for recycling these types of condensate:

-

Filling toilet flushes

In some buildings, air conditioning condensates are recovered and diverted to toilet flushes. This kind of system is typically seen in hotels, where each room has its own air conditioning unit and toilet. It’s possible to design a similar system for residential use, although the practice isn’t widespread because it isn’t cost-effective. -

Filling steam irons and steam generators

Air conditioning condensates are soft and pH-neutral, meaning they’re just as good for steam irons and steam generators as distilled or demineralised water (unlike hard water, which causes damaging limescale to form inside the appliance under the effect of heat). If you’re using tumble dryer condensates containing textile fibres, it’s best to run the water through some coffee filter paper first. -

General cleaning

Using condensates for everyday cleaning is a great way to save precious tap water. There really are no limits – from rinsing away sea water, to mopping floors, washing windows, shampooing carpets, or even cleaning dust off furniture and plants. -

Watering the garden

Condensates from air conditioning units and tumble dryers are almost too pure for plants, which require minerals and nutrients. But they nevertheless provide one of the key ingredients that plants need to grow: water! So there’s no reason not to water your garden with these condensates. After all, rain water is also the product of condensation, so it’s equally lacking in goodness. It’s nevertheless a good idea to enrich the water with minerals and nutrients, especially for indoor pot plants that have no other source of nourishment.

Is it safe to drink condensate water?

It’s absolutely not safe to drink condensates from combustion boilers because they contain toxic compounds.

It’s also a bad idea to drink air conditioning condensates. Like distilled or demineralised water, they’re not necessarily toxic. But they often harbour impurities from indoor air, as well as dust from the cooling system fins. Worse still, the bacteria that grow in stagnant water inside the drain pipes can sometimes make their way into the condensates – occasionally in the form of a concentrated biofilm that will make the water particularly unappetising. What’s more, drinking only pure water can deprive your body of essential minerals and nutrients, leading to long-term health issues.

Add new comment