Pump core: the history of an uncompromising miniaturisation

Piston pump cores are one of the foundations of Sauermann's industrial specificity in the condensate pump sector. Why is that? Because they are designed by the Group's R&D department in France and manufactured in France, whereas many other pumps on the market outsource the design and production of this essential component.

Long-term investment

The pump core is the central block of a pump: the component that draws in the condensate water and discharges it to a drain. That's why this component is so important, the backbone of a whole generation of mini condensate pumps for many years. The third and final generation of Sauermann mini condensate pump cores comes 23 years after the first, and 11 years after the second!

The design of the piston pump core must therefore be perfect in every respect, and its evolution must maintain its technological lead over the competition. After the second generation was patented under the name "APO2", the latest generation "NPO" from Sauermann brings a new edge to the market thanks to several major improvements that will be detailed later in this article.

Sauermann's focus on designing and producing its own pump core in-house means that it has complete control over the quality of manufacture of its various ranges of mini pumps for air conditioners. This is a crucial advantage over the competition, as most mini pumps on the market use a pump core manufactured externally by a third-party supplier. This is also part of the reason why it has been possible to label the new Si-20 and many other condensate pump models as "Made in France", as they are manufactured in the Chevry-Cossigny factory in Seine-et-Marne.

The power of experience

Sauermann has over 45 years of experience in the condensate pump sector and has been designing its own pump cores for 23 years. This is a lot of feedback from practical experience and listening to the needs of installers and users. Thousands of hours of research have perfected this essential component. Sauermann's mini pump cores have exceptional reliability statistics precisely because of this unique expertise: more than 10 million pump cores have been manufactured, with a reliability rate of 99.999% in production!

For the new NPO core, the final assembly and all quality tests are now performed by a special machine equipped with a robotic arm. This ultra-modern workstation significantly increases the fluidity of production while improving the reliability and quality of the manufacturing process.

Exclusive and patented technology

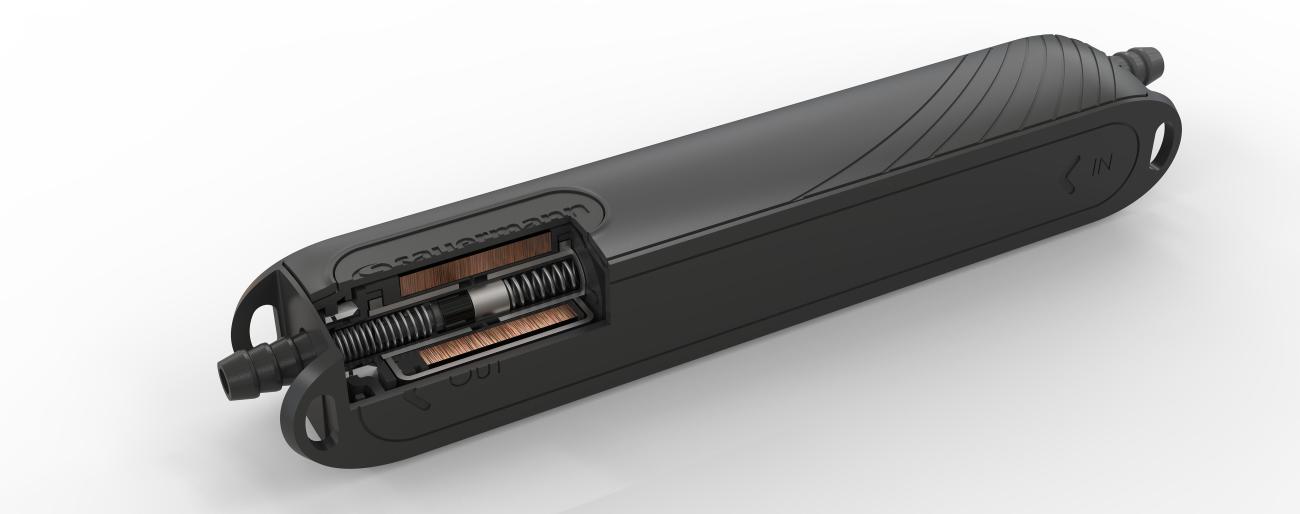

The APO2 and NPO are built around a patented Sauermann system called the Dual Wave Piston Pump. This is the only technology that uses the two oscillation cycles of the alternating current to make its pumping movement in a "round trip". The operation is therefore more energy efficient, and allows for a smoother and more fluid back-and-forth movement, reducing vibration and therefore noise during operation. The durability of the pump core is also improved as the smooth movement avoids the abrupt return of the piston by the sole effect of a spring.

Sauermann's latest NPO core goes one step further with a new patent: the copper coil is now mounted on a holder that can be attached directly to the motherboard PCB of the mini pump via a solderless press-fit system.

Miniaturisation and streamlining

The simpler the part, the more reliable it is. This principle has led Sauermann's R&D to reduce the number of components in the new NPO pump core by 40%. This simplification also brings another major benefit: a dramatic miniaturisation which results in an impressive 30% reduction in the total volume of the part compared to the previous APO2 generation!

This process of simplification and miniaturisation will enable the design of new, even smaller mini pumps to offer professionals unparalleled flexibility and ease of installation. A good example of this is the new Si-20, which can fit into the smallest corners of an air conditioning system.

Fewer parts also mean less raw material. This material saving makes the NPO core much more environmentally friendly and cost-effective.

No compromise on performance

Another achievement of the engineers is that this new NPO generation manages to keep its performance completely unchanged despite its simplification and miniaturisation. Its pumping power continues to lead the market: it is the only core pump to deliver a maximum flow rate of 20 litres/hour, with a record suction head of 3 metres. Its lifting potential is 10 metres, the highest on the market.

And to top it all off, this pump core is considerably quieter than the previous APO2 generation: from 22 to 19 dB(A)! This consolidates Sauermann's lead over its competitors in this field. For more information on the sound performance of the new NPO equipped Si-20 mini pump, please refer to this article.

Add new comment