Measuring Combustion Efficiency Properly on 90%+ Condensing Equipment (condensing boilers)

Combustion efficiency is a measurement of how well any given fuel is being burned and converted into useful energy (e.g.: heat, hot water, steam). The calculations are based on 3 MAJOR Factors:

1. Chemistry of the burned Fuel (e.g. Propane, Natural Gas, Oil, etc)

2. The CO2 percentage by volume after the combustion process

3. The NET temperature difference between the temperature of combustion gas & the Primary Air being used

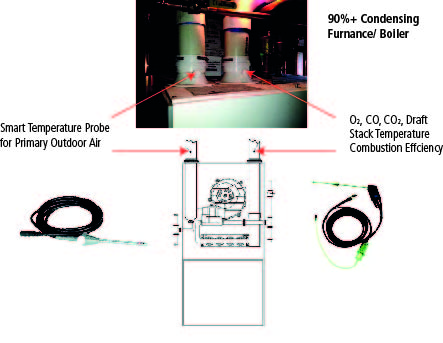

Condensing furnaces, boilers, and tankless water heaters use a different method of measuring the ∆T because condensing systems connected to suction pipes use OUTDOOR AIR as the Primary temperature (not the ambient room air temp). Furthermore, the Stack Temperatures of condensing systems are MUCH lower than atmospheric systems, so the importance of properly measuring the correct ∆T is much greater for accurate Combustion Efficiency calculations using your combustion analyzer.

High Efficiency, Condensing furnaces/boilers/water heaters connected to a suction pipe, the temperature of the combustion air must be measured. It is possible to measure the combustion air by inserting a temperature probe in the hole of the suction pipe if available (most manufacture’s have dual testing ports already for both incoming air & exhaust, please refer to their specifications of where to test). You might need to drill a hole if needed. If drilling a new hole, be careful to seal it up after testing is completed. In order to obtain an accurate Combustion Efficiency reading, the Smart Incoming Air Temperature Probe (included on all our “HE” Kits) must be inserted in the combustion air intake (while simultaneously the flue gas probe is inserted into the Flue Exhaust Stack) so that a True NET Stack Temperature is used in the efficiency calculation of the analyzer.