Is Measuring Draft Important?

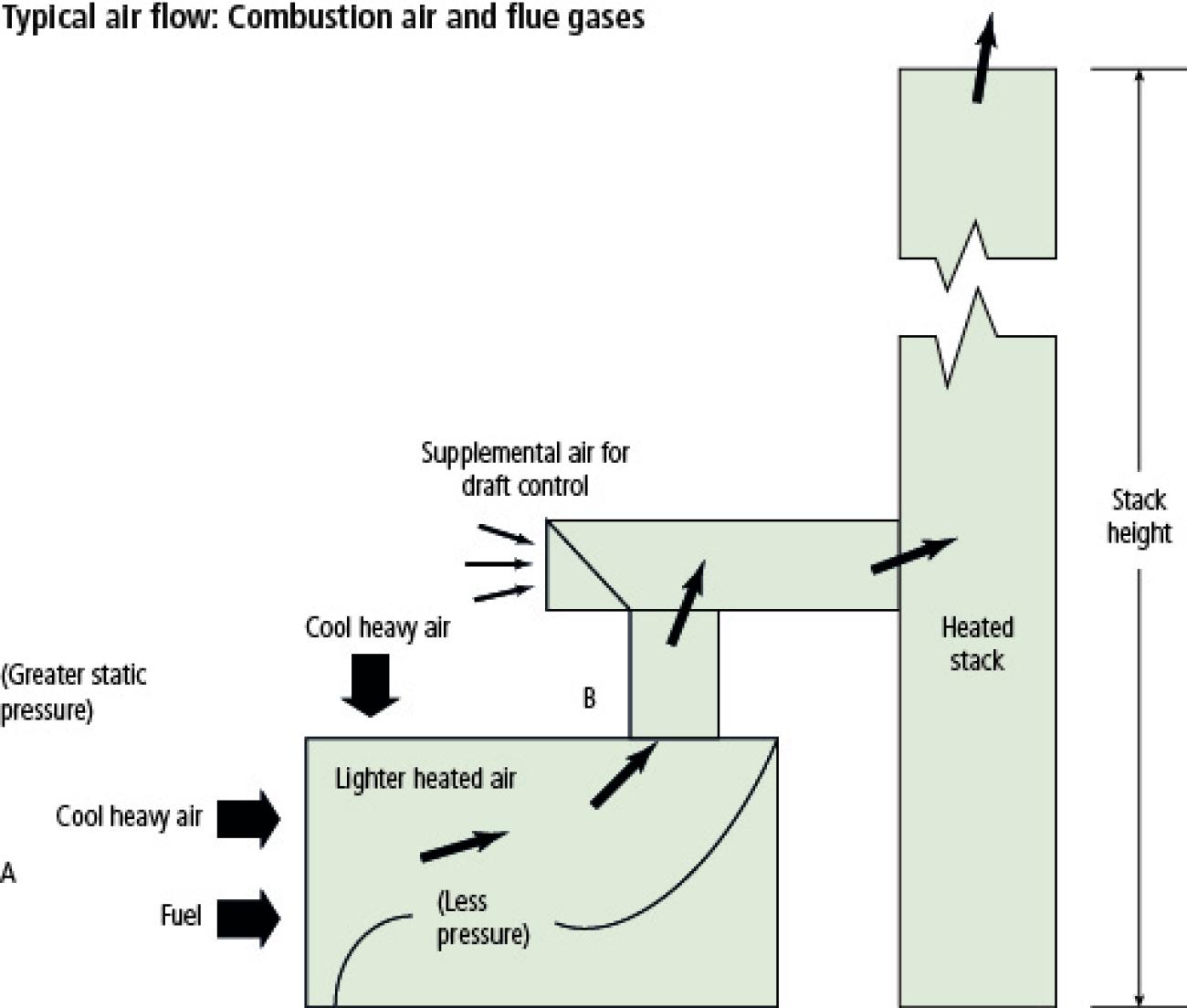

The pressure of the gases in the stack must be carefully controlled to ensure that all the gases of combustion are removed from the combustion zone at the correct rate. This draft pressure can be positive or negative depending of the boiler design: natural draft, balance draft, and forced draft boilers are the most commonly used in the industry.

Monitoring draft is important not only to increase combustion efficiency, but also to maintain SAFE conditions. Low draft pressures create build-ups of highly toxic gases such as carbon monoxide and highly explosive gases. These build ups may take place in the combustion chamber or may even be ventilated indoors creating the risk of injury and death. Conversely, extremely high draft pressures can cause unwanted turbulences in the system preventing complete combustion. Unwanted high draft pressures tend to damage the combustion chamber and heat exchanger material by causing flame impingement.

The following operating difficulties can result from uncontrolled draft:

- Poor combustion efficiency

- Pilot / Main Flame fails to light or is unstable, causing shutdowns

- Soot accumulations due to varying fuel-air ratio

The draft regulator (barometric damper) is located on the stack, is closed when the burner is off but opens automatically to pull air into the boiler when the burner is turned on. Accumulated soot and rattling are signs that the draft regulator needs to be adjusted. Too much air in the chimney wastes heat; too little air wastes fuel by failing to burn it completely. Testing Draft with our combustion analyzer ensures the system has the proper amount of air for the system to run safely and efficiently.

Example

Type of Heating System Overfire Draft Stack Draft

Oil, conventional -0.025 to -0.05 mbar / -.01 to -.02 inH2O -0.05 to -0.124 mbar / -.02 to -.05 inH2O

Gas, conventional N/A -0.05 to -0.01 mbar / -.02 to -.04 inH2O

Instrumentation Solution

All of our HVAC Combustion Analyzers are equipped to MEASURE DRAFT AUTOMATICALLY. Since Draft should be the 1st parameter tested during analysis, our analyzes are equipped with a DUAL Hoses probe allowing the user to automatically test Draft and Gas Analysis without having to continously remove / reinstall the probe into the stack. Most competitors use a single hose system that can be time consuming to test.