CASE STUDY: Clean Room Environmental Monitoring System

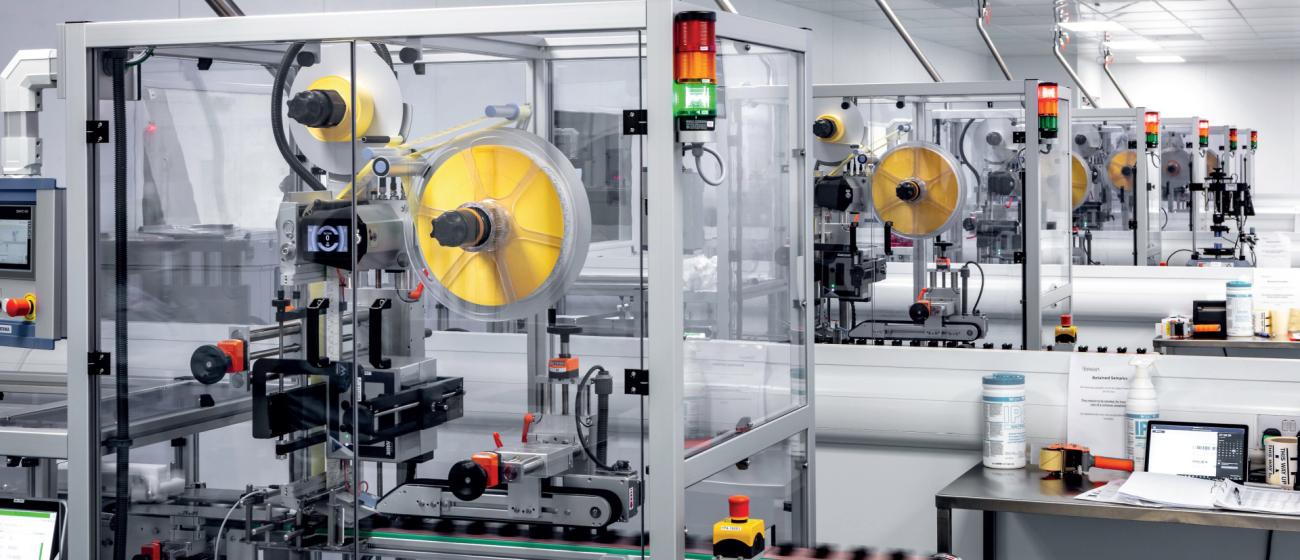

In the first quarter of this year, Sauermann UK delivered comprehensive environmental monitoring for one of the world’s leading pharmaceutical packaging companies based in Yorkshire.

The installation required continuous and instantaneous information about the maintenance of pressure differential between ISO graded spaces for its packaging production lines. Sauermann responded with the supply of wall mounted KIMO CPE 310-S environmental transmitters combined with a vendor agnostic software and electronic control system from CIONICS Ltd. The CIONICS software continuously polls the KIMO units to extract and record differential pressure, temperature and humidity.

Always connected monitoring

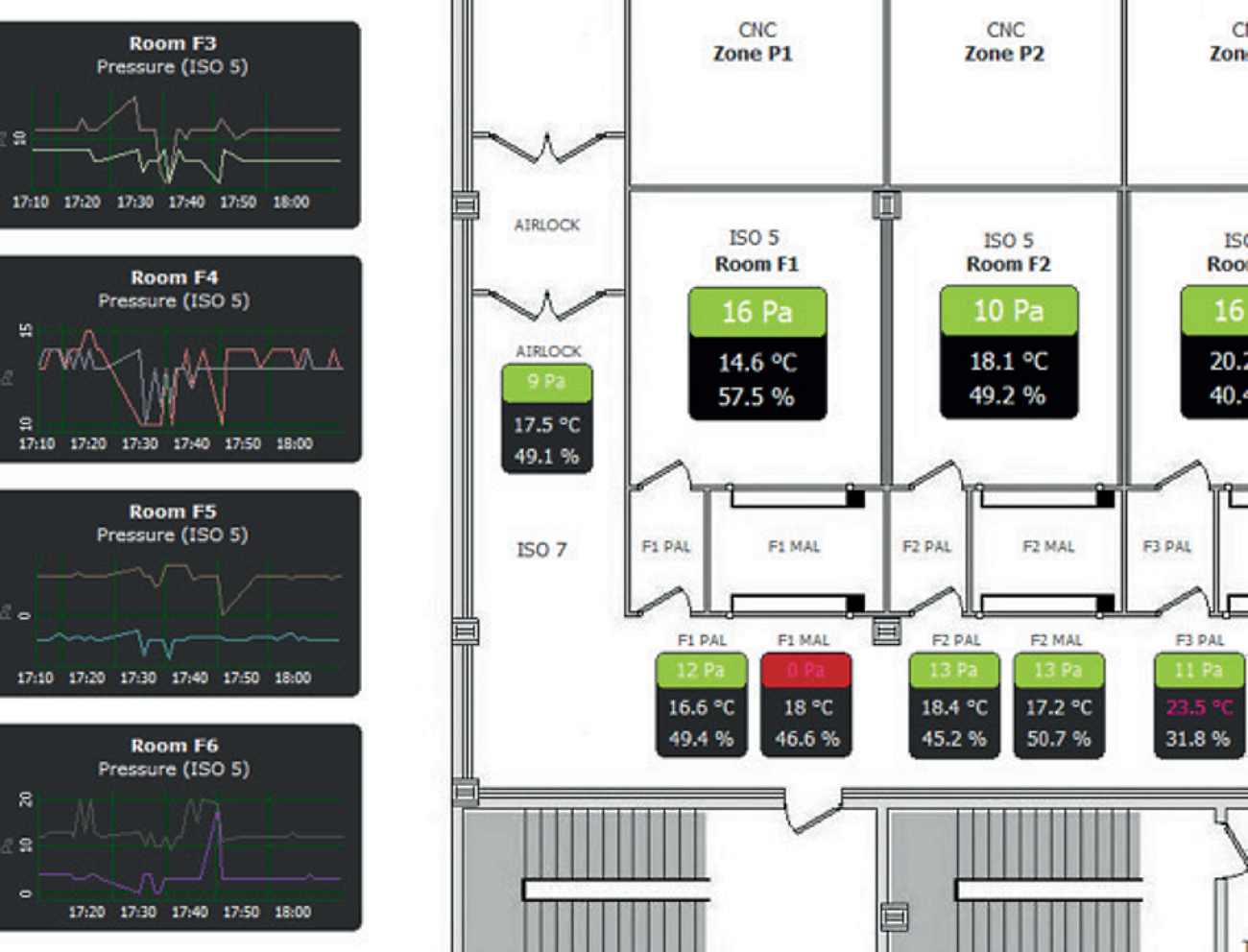

The transmitters conveniently fit into recesses embedded in support columns and walls with high visibility, providing smooth and easy to clean surfaces. Compliance is governed through the application of alarm thresholds set against data received from each KIMO transmitter. On the Packing room floor the CIONICS software enables the visualisation of operational compliance for pressure in real-time through a tri-colour indicator system located in each ISO 5 space. Operatives in each space communicate with the system via wireless web enabled tablet PCs. On event, operatives provide acknowledgements and other actions using touch screen responses which are time and date stamped and recorded.

Large format screens in ISO 7 areas deliver a comprehensive view of the operating status of all monitored spaces.

The CIONICS ONCALL-FINESTRA system features a powerful historian designed to satisfy industry regulators and Quality Assurance. Alarm events, change management and system activity information is stored on the system in encrypted log files. Quality Assurance and Operations management have access to a graphing engine, system reports and an alarm manager, all of which are available on demand to provide event duration information and event history in pre-formatted pdf reports.

Easy visualisations and alerts

Performance analysis for pressure delivery can be derived from single or multiple series graphs comprising groups of sensor values enabling instant access to correlations. This is particularly useful in the visualisation of pressure cascading as people and product pass through pressurised areas and determining working comfort for operatives in PPE equipment. Graphical data can be shown in tabular form for export to spreadsheets for further analysis or use by HVAC contractors and maintenance personnel. The Clean room systems operate continuously.

During out of hours periods such as week-ends and public holidays, the company has visibility of the EMS system remotely via web access, conditionally sent emails and SMS messaging. The SMS system is uniquely bi-directional. This means that recipients of such messages can be automatically alerted to the most severe alarm conditions such as a power failure where they can take ownership and suppress further alerts in providing a remedy.

At its core is SQL Server and SQL Connect. System security operates within the Microsoft SQL Server security model. The system can be configured to support other critical plant such as generators, UPS systems and HVAC using a variety of industry standard protocols. The ONCALL-FINESTRA system is customisable, very scalable and vendor agnostic the ideal engineering solution for Sauermann UK.

Contact: Ian Mellor, Sauermann UK Ltd

Add new comment