Importance of Portable Emissions Analyzers for Process & Emissions Optimization at a Cement Plant

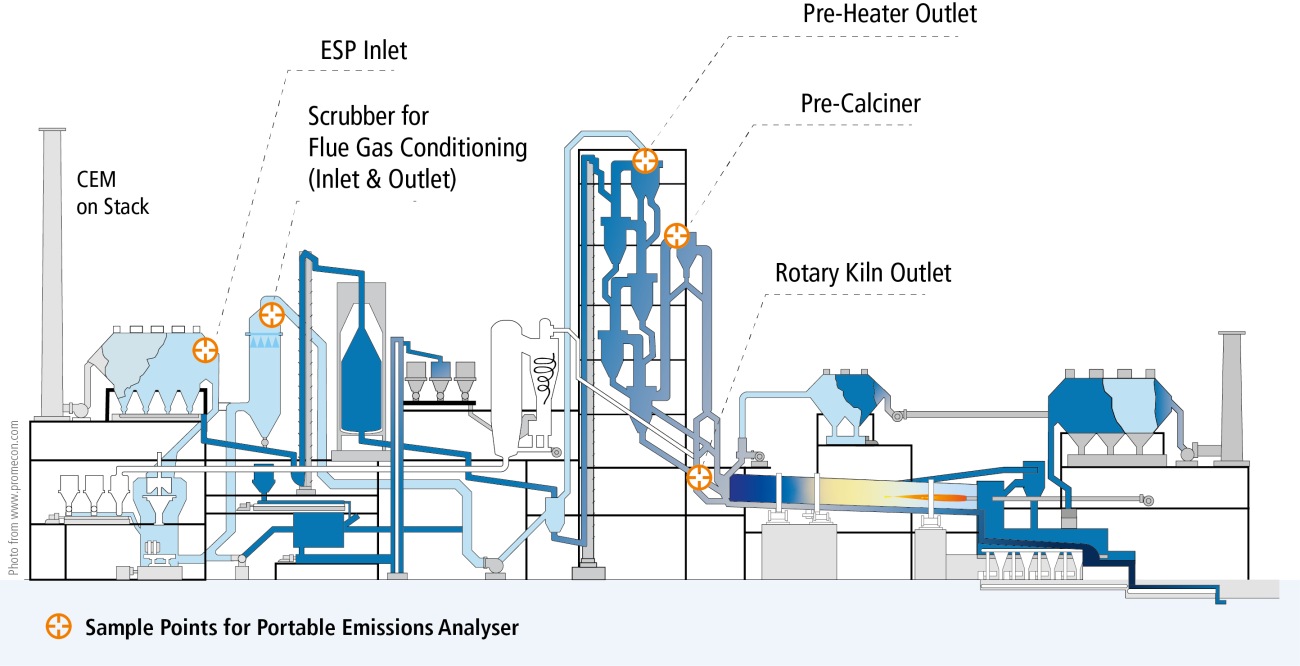

There are many locations that should be measured & monitored with a portable emissions analyser to maximise product quality, combustion efficiency, safety, & emissions reduction in a cement plant including the following:

- Rotary Kiln gas outlet – O2, CO, NOx, CO2, SO2, CxHy, temperature

- Pre-Heater & Pre-Calciner – O2, CO, NOx, CO2, temperature

- Flue Gas Conditioning System – CO, NOx, SO2, CO2 such as scrubber, SCR (Selective Catalytic Reduction), SNCR (Selective Non Catalytic Reduction)

- Electrostatic Precipitator (ESP) inlet – CO

- Main Stack for Continuous Emissions Monitoring system (CEM) back-up – O2, CO, NOx, CO2, SO2, CxHy

Although a CEM measures the emissions from the main stack for regulatory compliance, a portable flue gas analyser with a high temperature sampling probe is fundamental to measure the parameters that significantly affect the cement process control & product quality, the kiln combustion efficiency, and the emissions generated throughout the cement plant.

The levels of CO, CO2, NOx (NO & NO2), SO2, & CxHy as well as gas temperature should be measured to ensure optimal combustion efficiency of the kiln that will result in fuel savings and reduced emissions.

Instrument Solution: Si-CA 8500 Portable Emissions Analyser

The Si-CA 8500 portable emissions analyser can easily be used for accurate emissions measurements of O2, CO, CO2, both NO & NO2 for True NOx, SO2, and CxHy throughout a cement plant.

The Si-CA 8500 flue gas analyser also has sample extraction and conditioning well suited for cement plants with high temperature (2200 °F / 1200 °C) probes, dust filtration, and a built-in thermoelectric chiller.