Using Portable Emissions Analysers for Optimising the Performance of a Cogeneration Plant

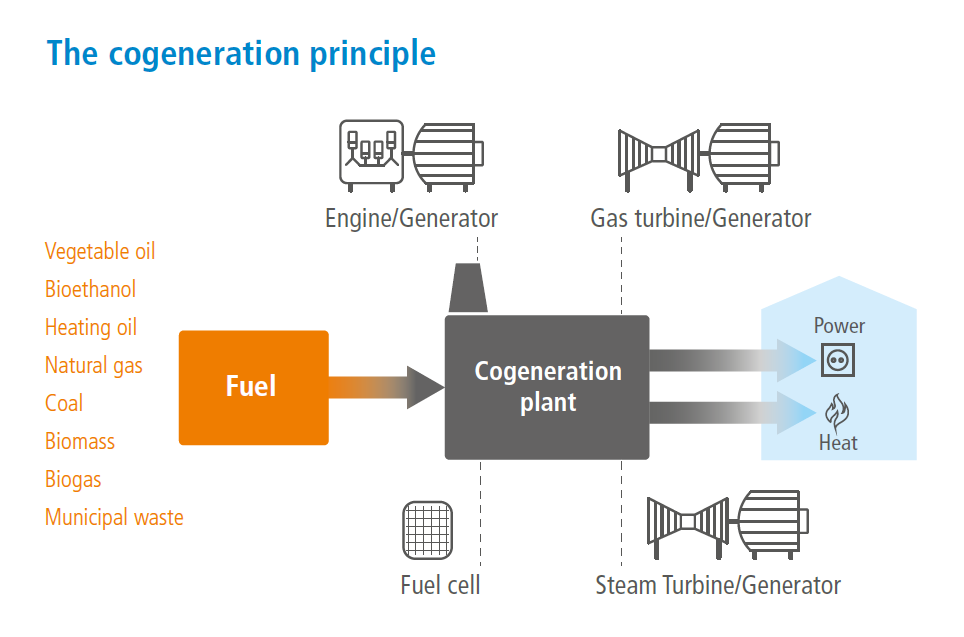

Cogeneration, or combined heat & power (CHP), is the utilisation of boilers, turbines, and/or engines to simultaneously generate electricity power and heat that can be useful in several ways such as for hot water, steam, district heating, and water desalination.

Some types of cogeneration process applications include the following:

- Flue Gas Temperature

- O2, CO, & CO2

- CxHy Hydrocarbons

- Total NOx (NO + NO2)

- SO2 for SOx

- H2S

Optimising the overall performance of a cogeneration plant for fuel savings, combustion efficiency, maintenance, safety, and emissions reduction purposes can be done by using a portable emissions analyser to monitor important parameters at many different locations in the CHP plant including the following:

- Industrial Processes – Power Plants, Refineries, Chemical Plants, Food & Beverage, Pharmaceutical

- Waste Incineration & Management – Industrial, Municipal, Medical & Hospital, Landfills

- Burning Biomass – Pulp & Paper Plants, Saw Mills, Sugar Mills, Peat & Wood Waste

- Institutional – Schools, College Campuses, Prisons, Hospitals

Instrument Solution: Si-CA 230 Portable Gas Analyser and Si-CA 8500 Emissions Analyser

The Si-CA 230 Portable Gas Analyser and Si-CA 8500 Emissions Analyser can easily be used for accurate measurements of flue gas temperature, O2, CO, CO2, both NO & NO2 for True NOx, SO2, H2S, and CxHy hydrocarbons throughout a cogeneration plant.

The instruments include a PC software with wireless connectivity to monitor, graph, and record all measurements and calculations.

The Si-CA 230 Portable Gas Analyser also comes with a free Mobile App for iOS and Android for Real-Time Display & Control of measurement data.