Measuring Combustion Efficiency and Emissions from Sugar Mill as Cogeneration

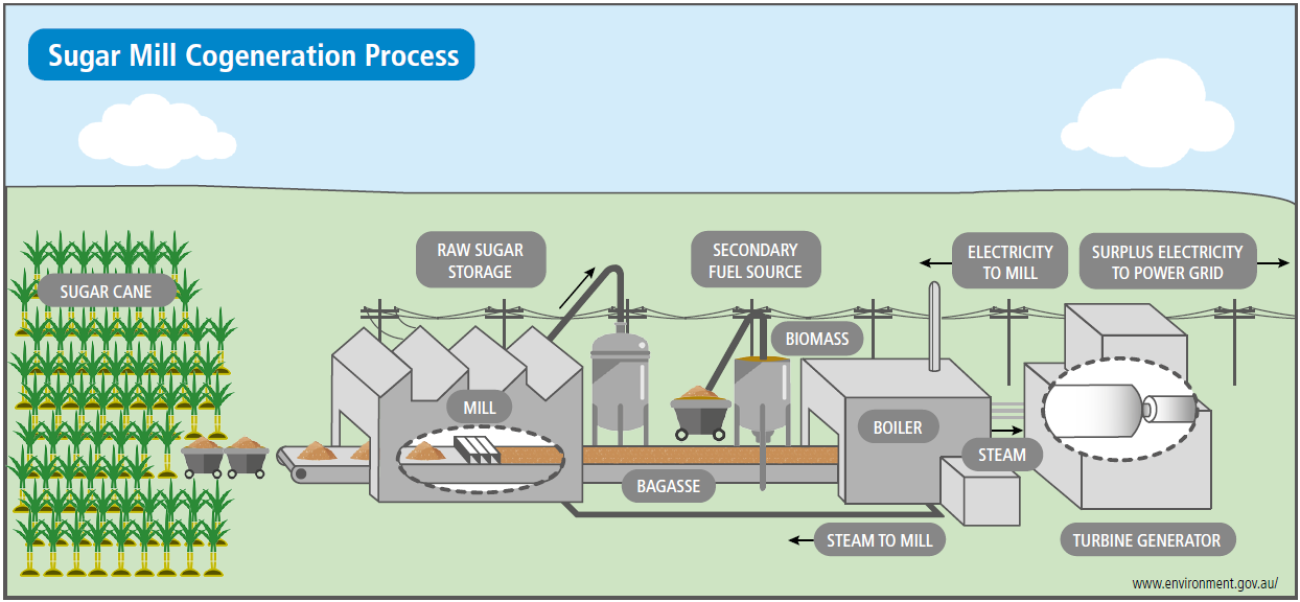

For many years, sugar mills have burned bagasse, the fibrous byproduct of the processing of sugarcane, using special boilers that produce the steam needed to help break down the sugar cane.

As the cost of powering this equipment by burning fossil fuels has steadily risen, the use of biofuel cogeneration as a source of power production has become more prevalent. Many sugar mills have updated their bagassefired boilers and linked them to generators that produce electricity used to power the mill’s operations and to be sold to the local power grid.

Optimising combustion efficiency and achieving cleaner burning throughout the process will generate more electricity and steam, and reduce harmful emissions. These results can be achieved if the equipment used in the cogeneration process is frequently tested using a portable emissions analyser.

Combustion Efficiency & Safety

Measuring the levels of O2 (oxygen), CO (carbon monoxide), and CxHy (hydrocarbons) being emitted from bagasse-fired boilers will inform the mill’s operators if their equipment is burning the biomass cleanly and efficiently. Achieving higher efficiency will allow them to minimise the amount of auxiliary fossil fuel being used to help power the system.

Environmental Emissions

Monitoring the CO2, SO2, and NOx emissions from the system is necessary to ensure compliance with current environmental regulations and to minimise environmental and health hazards. Emissions measurements should also be taken before and after the flue gas cleaning system to ensure the efficient elimination of any corrosive components present in the system.

Instrumentation Solution

The Sauermann Si-CA 230 is a handheld analyser for the measurement of O2, CO, NO/NOx, CxHy, & CO2.

The Sauermann Si-CA 8500 is the complete emissions monitoring solution for the measurement of O2, CO, CO2, NO, NO2, SO2, H2S, & CxHy.