Three years on: five key benefits of the Sauermann and KIMO merger

Three years ago, KIMO Instruments merged with Sauermann Industrie and Sauermann Group announced the gradual phase-out of the KIMO brand in favour of a unified Sauermann brand.

KIMO was taken over by Sauermann Industrie in 2015 and became fully absorbed into Sauermann Group in January 2020. The merger marked the official culmination of a major branding shift: henceforth, all new measurement instruments released by the Group would be Sauermann- rather than KIMO-branded. At the same time, KIMO completed its transition by ceasing to be a separate legal entity and becoming a fully-fledged part of Sauermann Group.

Here, we look back on the five biggest success stories to come out of this merger.

1. Deeper HVACR expertise

Sauermann and KIMO employees have combined their expertise to better support HVACR industry professionals:

- Sauermann’s teams have contributed their knowledge of condensate management for air conditioning units, boilers and cooling systems with installers and maintenance engineers.

- KIMO’s employees have brought to the table deep insights into indoor air quality measurement, with a special focus on HVACR applications.

2. A new generation of products backed by enhanced R&D

With its new, more robust organisation, the Research & Development team is now able to address today’s environmental challenges and chart a path to an increasingly connected future. This progression is evident in the new generation of Sauermann-branded instruments:

- The DBM 620 air flow meter, the first instrument to offer air change rate calculation via the accompanying SmartKap app.

- The HVACR range, which delivers the full range of premium measurement instrument capabilities via the free Si-HVACR Mobile App.

- The Si-CA 030, 130 and 230 combustion gas analysers with touch-screen display, which provide comprehensive analysis in record time plus auto-generated reports via the Sauermann Combustion app.

The strength of its R&D capability is why Sauermann is one of only a handful of mini pump manufacturers with a patented, internally designed and produced core pump technology – the third generation of which can be found in the new Si-20 model.

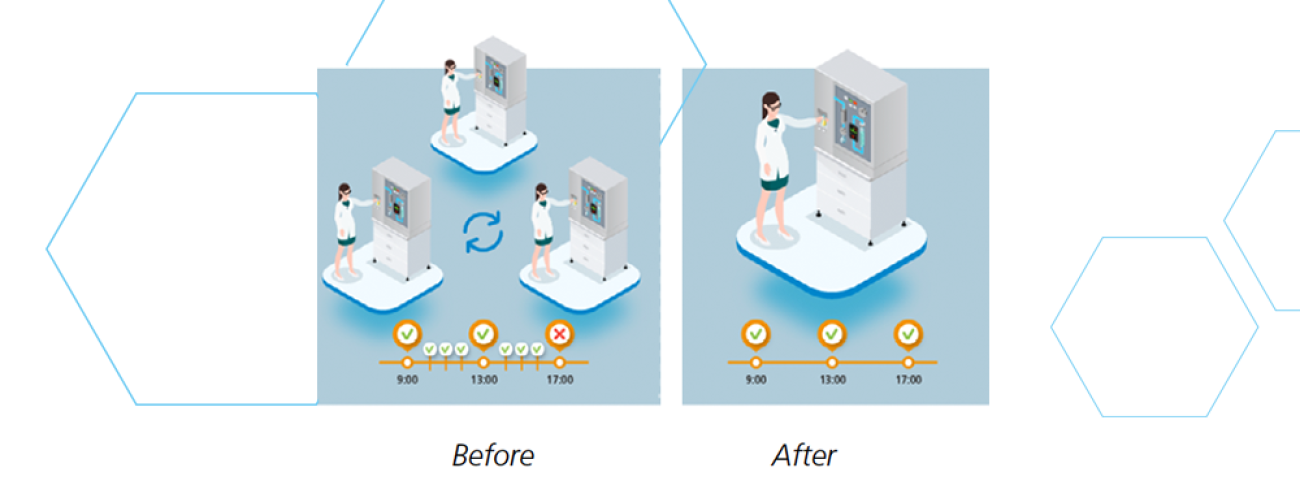

3. Modern production facilities that set new standards for agility and quality

The merger has given the Group the critical industrial mass needed to embark on an ambitious modernisation programme, with a focus on embracing the industry 4.0 era, boosting productivity and raising the bar even higher for quality:

- At one of our measurement instrument factories, we have installed quality assurance cameras at the end of the assembly line, as well as an automated vertical storage system that dramatically increases store space and efficiency.

- The finalisation and quality assurance processes for the core technology in our mini pumps are now faster and automated thanks to a brand-new special machine with a robotic arm.

- Our cutting-edge in-house metrology laboratories, spanning 800 sq m of space and covering all air parameters, provide instrument testing, certification and calibration services.

The merger between two experienced industrial entities means the Group retains firm control over its manufacturing, delivery and customer-facing processes, applying the same exacting criteria worldwide. The critical design and production phases continue to be handled in-house in accordance with KIMO and Sauermann’s quality standards.

4. Closer market alignment through process digitalisation

The merger between KIMO and Sauermann Industrie has coincided with a modernisation drive across all aspects of our business. Digitalisation is central to this process as we look to bring the Group closer to customers and better reach the market through every available avenue.

New technologies are helping us cater to the merged entities’ preferred sales channels in a more targeted and flexible way. Sauermann has contributed its expertise and reputation in HVACR distribution, while KIMO has imparted its experience in targeting specifiers and building commercial partnerships worldwide.

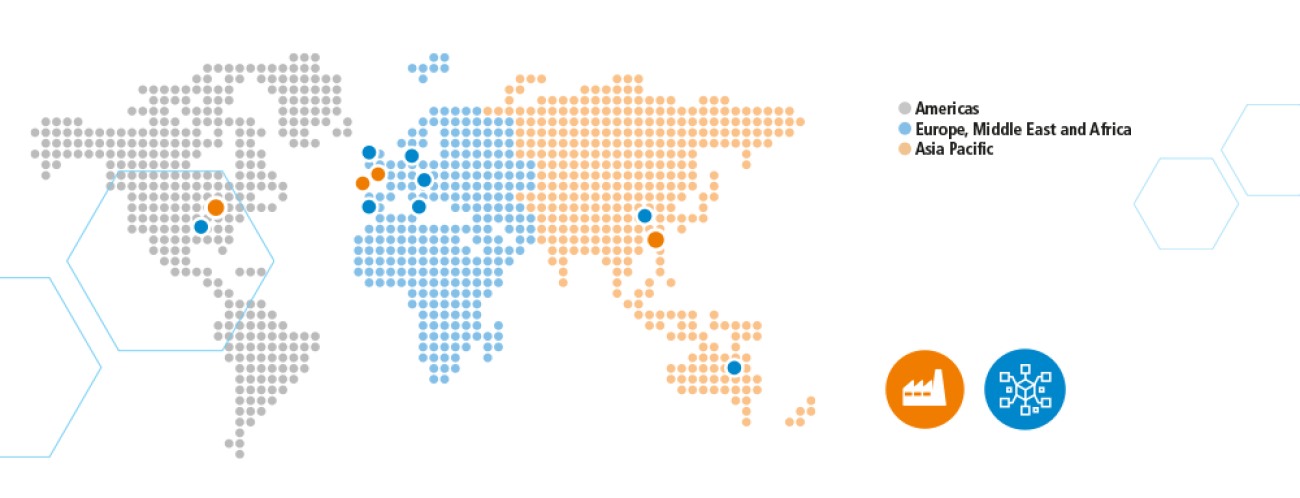

5. A bigger global footprint

The pooling of KIMO and Sauermann’s resources has laid the foundation for an expanded global presence:

- The Group has 12 sites and 4 production facilities in 8 countries, and the Sauermann brand is present in more than 100 countries worldwide.

- The Group employs 400 people representing 25 different nationalities.

- The Group is building on its existing footprint in three regions – APAC (Asia-Pacific), EMEA (Europe, Middle East & Africa) and AMER (Americas) – and is exploring new markets.

A new era for indoor air quality

Under the unified Sauermann brand, KIMO and Sauermann are stronger than ever, with many new products in the pipeline. These include:

- New cutting-edge, high-precision measurement instruments, which are making their way onto the market.

- New mini condensate removal pumps, which will feature our new core pump technology, setting new standards for compact design, reliability and whisper-quiet operation.

- A completely revamped and modernised line of measurement instruments, which should help heating and air conditioning professionals work much more efficiently.

- And much more besides!

Add new comment