Ten checks to prevent water leaks from air conditioning units

A water leak can cause a lot of damage, especially when it goes unnoticed. Sometimes, the resulting damp can be hard to spot – and only becomes apparent when it’s too late. That’s why it’s important to stay on your guard, and to make sure that condensates are being drained properly from your air conditioning unit. Here are some things you can check to prevent disaster – or at the very least to troubleshoot leaks.

| Note for domestic users: First and foremost, make sure your air conditioning system is monitored by a professional by arranging an annual service. Ideally, you should book in this service after winter when your air conditioning unit has been out of use for an extended period of time, or when it’s been used in heating mode (in which case the condensate flows to the outdoor unit, leaving the drainage system for the indoor unit unused). |

1. Check that the unit is fitted with a suitable condensate removal pump

If the condensate removal pump isn’t appropriate for the air conditioning unit, it might not have enough drainage power or the pumping flow rate might be too low. In both cases, the condensate won’t drain away properly. This can cause the liquid to overflow, resulting in a leak.

That’s why it’s important to check that the pump is powerful enough to cope with the length of the drain tubes, and that it can handle the amount of condensate produced (this value is determined by the power of the air conditioning unit and by the average humidity of the indoor air).

You can use our Condensate Pump Finder tool to select the most suitable pump for your system.

2. Check that the unit and the pump detection system are horizontal

If it isn’t perfectly horizontal, the pump detection system (a tank containing a float) can overflow before alerting the pump that condensate needs to be removed. The air conditioning unit itself also needs to be fitted perfectly horizontally so that the slight slope in the condensate tray is oriented in the right direction (i.e. the direction in which it is to be drained).

Since these types of systems can move over time, you should use a spirit level to check that everything is still horizontal (in both directions).

![]()

3. Check that the pump isn’t installed somewhere that gets too hot in summer

Condensate removal pumps typically include a safety system that protects them by switching them off above a certain temperature. There’s no reason for this safety system to trigger in normal circumstances. But if the pump is installed in a place that’s inadequately protected from direct sunlight – such as in an attic with a poorly insulated or uninsulated roof – this can cause the system to kick into action. So it’s important to pay attention to little details like these during hot and bright summers, and especially during heat waves.

![]()

4. Check that the drain tube isn’t blocked

A flexible PVC condensate drain tube can become blocked – and bugs and insects are common culprits. Spiders, for instance, can build cocoons inside a tube , which act as highly effective plugs! This kind of problem often occurs in air conditioning units with gravity-fed (non-pumped) condensate drainage systems, because the very low fluid pressure allows the plug to build up until the tube becomes completely blocked. Likewise, a build-up of biofilm can eventually block a tube. Another important detail to check!

![]()

5. Check that the drainage system has been cleaned after winter

More generally, the condensate drainage system should be inspected from end to end to make sure that it’s been cleaned. Check the indoor unit’s condensate tray for an excessive build-up of dirt. It’s especially important to ensure that the pump detection system is as clean as possible, otherwise biofilm – which will have dried out after a long period of inactivity – could cause the float to become stuck. This article describes how to clean your condensate removal pump.

![]()

6. Check that the drain tubes aren’t pinched

Even if your system is almost brand-new and perfectly clean, it’s still possible for condensate to become obstructed. The clear tubes, which form the majority of the condensate drainage system, can sometimes twist and turn the wrong way at connecting points, causing them to pinch and block or limit the flow of liquid. This may seem like an absurd mishap. But it’s quite common, since the tubes themselves are extremely flexible, like a hosepipe.

![]()

7. Check that the pump is functioning properly, even when the air conditioning unit is switched off

You can use a priming squeezie bottle to simulate the flow of liquid, allowing you to test the entire condensate drainage system. Be careful to only add a small amount of liquid at a time: don’t squeeze a full bottle of water into an air conditioning unit at once, as the flow rate will be too high!

It’s also important to test whether the pump is effectively removing the liquid you add when the unit isn’t in use. The pump should be able to operate independently of the air conditioning unit, which can continue producing a flow of condensate long after it’s been switched off.

Likewise, you should check that the pump alarm is properly connected to the air conditioning unit. That way, the alarm will automatically switch off the unit if the pump malfunctions, thereby avoiding a condensate leak.

![]()

8. Check all the joints to make sure they’re secured in place and watertight

The joints on each tube connector upstream and downstream of the pump should be secured in place with wire clamps. As the clear tubes age, they can stretch at these connecting points. Without a clamp, they could ultimately come loose or start leaking. This is another important detail to check when installing and servicing an air conditioning unit.

![]()

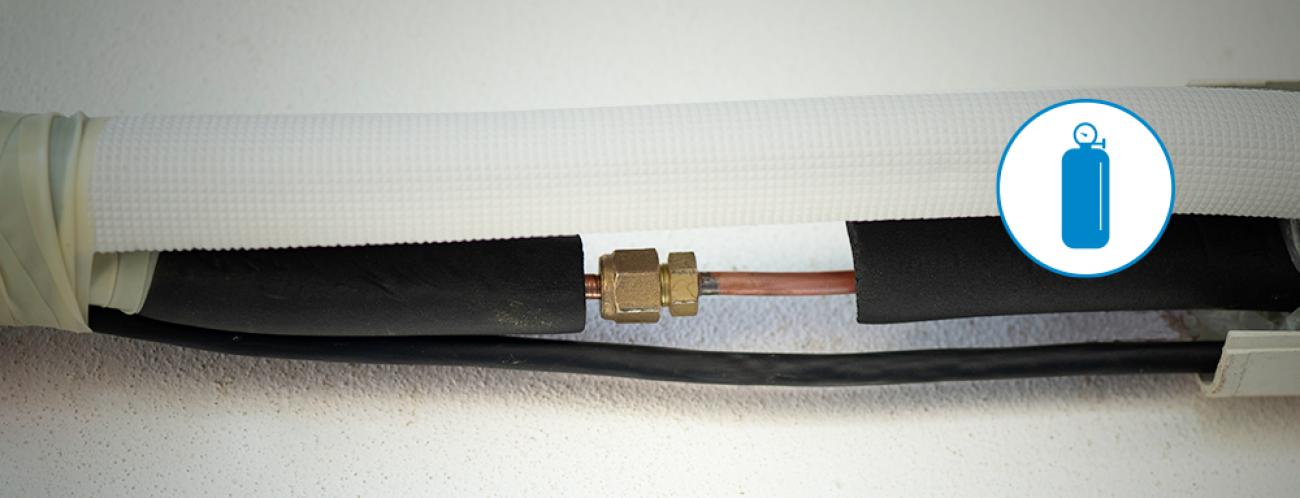

9. Check that the refrigerant gas circuit is properly insulated

It’s extremely important to insulate the copper tubes that form the refrigerant gas circuit. This system, in which the fluid undergoes a phase change, is highly sensitive to temperature variations. Improper insulation can therefore lead to a significant drop in performance. And in some cases, a tube might be so cold that frost forms on its surface when it’s exposed to the open air. It’s imperative to isolate these tubes with an appropriate protective sleeve, since the frost will inevitably melt, leading to problematic leaks and causing water to infiltrate into the wall that the copper tube passes through.

![]()

10. Check the fins and dust filters for clogging

It’s also important to check that the ventilation system itself is clean. Here, dust is enemy number one! If the fins are excessively clogged, the air blown by the fan will no longer be able to pass through. Frost can then form on the fins, in which case the partially cooled air will find an alternative path, bypassing the condensate tray and leading inevitably to a leak.

A similar situation occurs if the air filter, located upstream of the fan, is excessively clogged up with dust. In this case, the fan will become starved of air, causing frost to form on the indoor unit’s fins. And when it melts, this liquid will end up in an unwanted location.

Note that all of these checks are performed by air conditioning engineers as part of a standard service.

Add new comment