Measuring air flow rate at an air vent: getting it right

Air vent measurement is no easy task. It requires different methods and instruments depending on the type of vent in question. Following the tips in this article will ensure you get your measurements right.

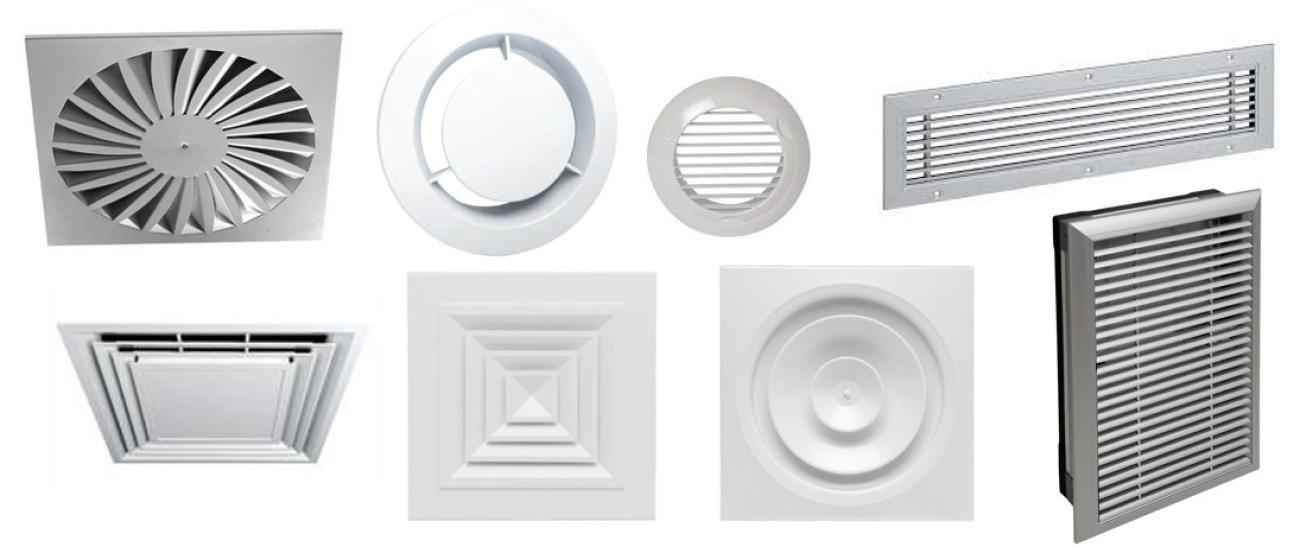

The type of vent will determine both what measurement methods you need to employ, and what instruments you should use to measure the air flow into or out of the vent. In short, the task involves measuring the air velocity or pressure in order to calculate the total flow rate according to the surface area of the vent.

One-way air vent

A one-way air vent is a flat grille through which air flows in a straight line. Their conventional design lends itself to straightforward, user-friendly instruments:

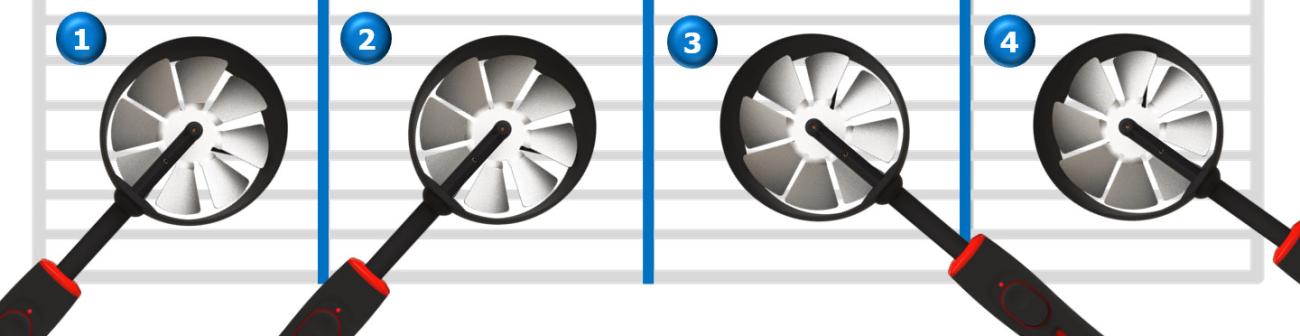

- Vane thermo-anemometer:

This is a classic type of instrument for this application, spanning a reasonable measurement range (0.3 to 35 m/s) and providing a perfectly adequate degree of accuracy. These instruments are extremely easy to use, as long as they’re oriented in the right direction (as indicated by the arrow on the vane probe surround).

- Hotwire thermo-anemometer:

Because this instrument is more sensitive than a vane probe, it can measure air flows as low as 0.15 m/s, with three times the measurement resolution at low speeds. For this reason, these instruments can take reliable measurements at air vents, provided they’re always held the same distance away (around 15 cm).

| Their high sensitivity also makes hotwire thermo-anemometers suitable for airtightness testing, since they can detect even the tiniest air currents in the most unlikely of places. |

When it comes to measurement methods, there are two options:

-

Scanning:

This method is only possible with a vane probe, since a hotwire probe is overly sensitive to the disruptions caused by movement during scanning. With the “Automatic Average” function switched on, the probe is then swept horizontally and vertically across the entire surface of the grille. -

Zoning:

This method involves taking readings at different points then calculating the average. It can be done with a vane probe or a hotwire probe. The grille is divided into several identical zones, and a measurement is taken for each zone. The instrument then averages these figures to give a final measurement.

| An elbow probe extension makes it easier to take measurements on ceilings. When using a hotwire thermo-anemometer, a small 15 cm rod can be fitted to the extension to keep the probe at a uniform distance from the ceiling and to prevent it from shaking, which can affect measurement accuracy. |

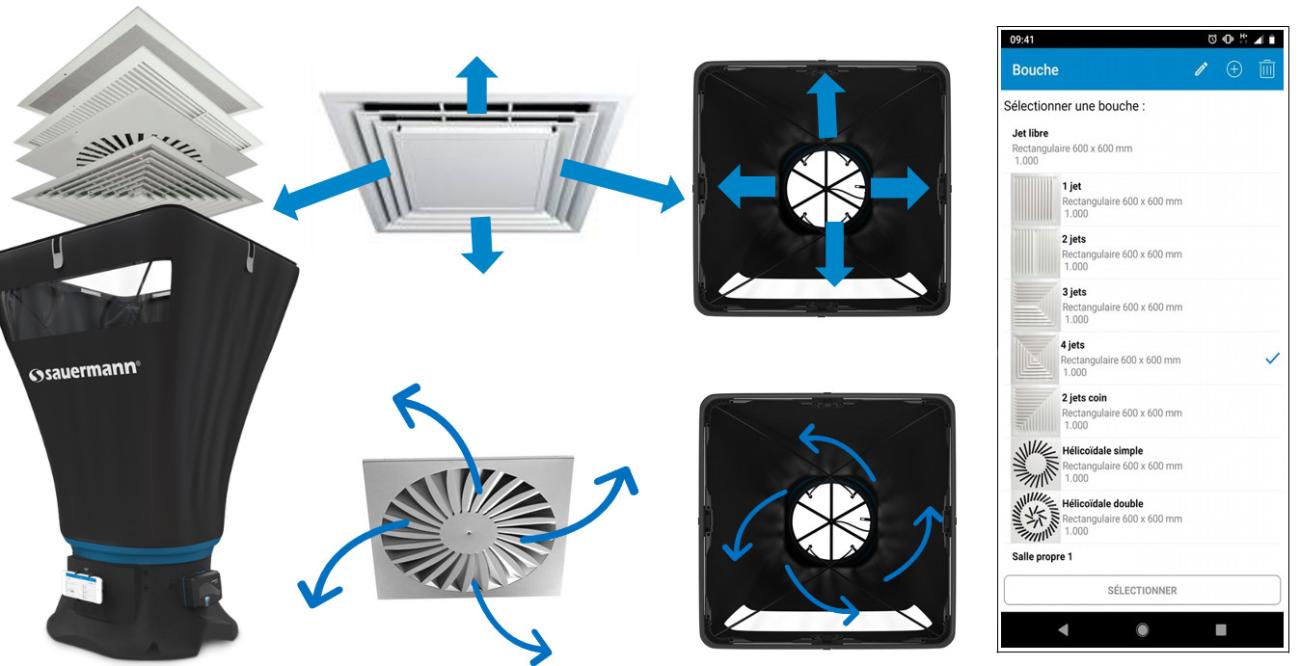

Diffusers

Diffusers are air vents that blow in all directions simultaneously, keeping air moving gently around a room without the occupants feeling a draught. Since the air trajectories are much more complex, the only tool for the job is an air flow meter.

An air flow meter is the only instrument that can take reliable measurements at diffusers, irrespective of their design. It includes a foldable, swappable air flow hood (available in various shapes and sizes) and a differential pressure measurement grille, both linked to a multifunction measurement device.

As the most sophisticated type of instrument used in this sector, an air flow meter is capable of measuring multiple parameters at once: air flow, air velocity, temperature, humidity and pressure. Our DBM 620 air flow meter is the first of its kind that can calculate the hourly air change rate in a room by combining air flow readings from all vents.

| The principle that if you can do something complicated, you can do something simple holds true: an air flow meter is equally suited to taking measurements at one-way air vents. The only drawback is that it’s oversized for small extractor fan vents. |

Extractor fan vents

Since extractor fan vents aren’t flat, the only way to obtain reliable air flow measurements is to use an air flow cone. The simplest set-up is to use a cone with a vane thermo-anemometer, although it’s also compatible with a hotwire thermo-anemometer, provided the probe is centred in the middle of the cone.

The cone itself also needs to be precisely centred over the vent and placed flush to the wall to prevent pressure leaks and to avoid disturbing the air flow.

These cones come in a range of sizes to fit different vents, and each shape and size is designed for a particular air flow range (lower or higher). Each cone also has a specific coefficient, which needs to be applied to the reading to compensate for the turbulence caused by the air flowing inside the cone. That’s why our measurement instruments come with the coefficients for our cones pre-loaded into their memory.

Manometers are another useful instrument, this time for taking static pressure readings in the inlets of small extractor fan vents. These readings, in turn, can be used to deduce the air flow value with a reasonable degree of certainty.

| These cones aren’t designed exclusively for extraction systems: they’re also compatible with small vent grilles and diffusers (up to 45 x 45 cm). Just remember to reverse the direction of the arrow on the vane probe or hotwire probe! |

To learn more, watch this webinar (in French), where our expert takes a deep dive into air vent measurement techniques.

Add new comment