Air flow: six reasons why DEBIMO blades are the superior choice

When it comes to permanent air flow measurement in ventilation ducts, there are lots of options out there. These instruments are vital to building ventilation system management, but they’re not all equal. For many, making the right choice can seem daunting. But the answer is simple!

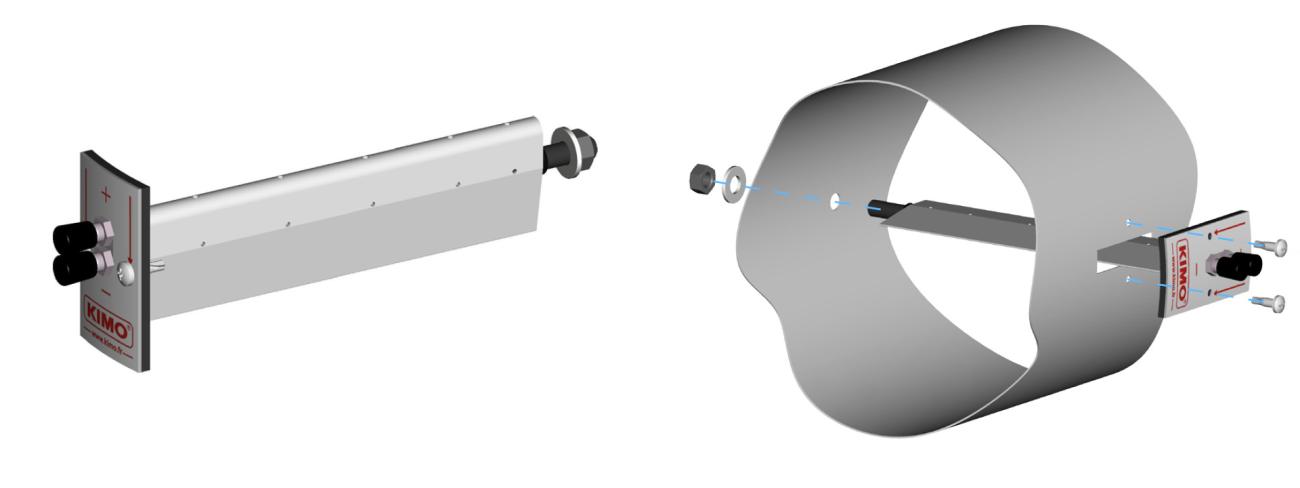

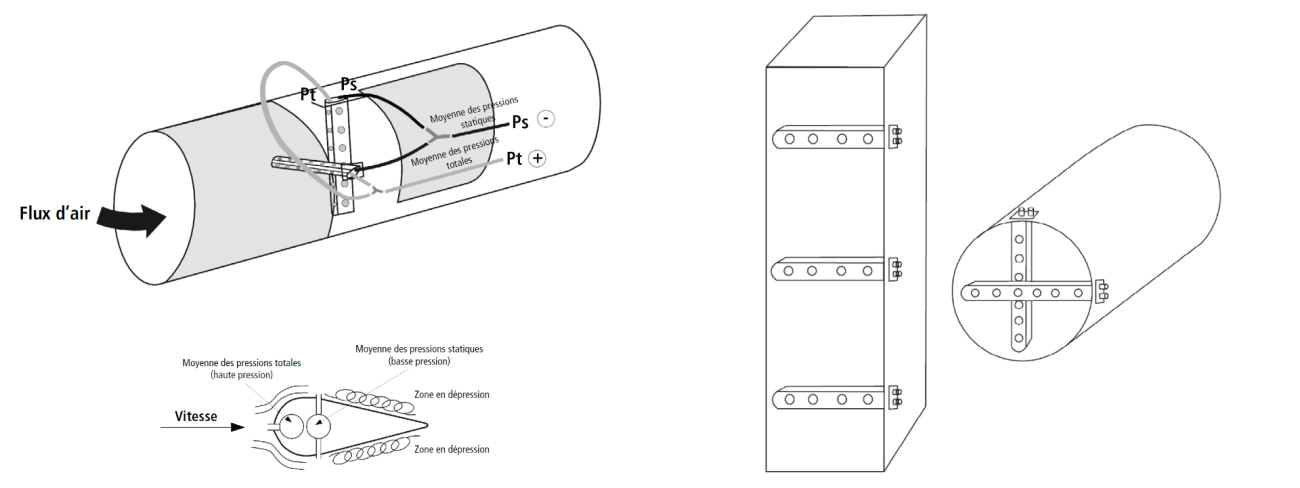

DEBIMO blades are among Sauermann’s best-sellers, drawing on over 45 years of expertise in the field. These measurement instruments are a modernised version of the Pitot tube. Shaped like an aircraft wing, they feature multiple ports for measuring both static and total pressure.

The average differential pressure between these two sets of data points, known as “dynamic pressure”, provides a highly reliable indication of the average air velocity across the entire surface of the duct. This, in turn, gives an accurate value of the air flow through the pipe.

Here are six reasons why this solution quite simply outclasses the rest of the competition:

1 - Ultra-reliable design

DEBIMO blades, initially developed by Kimo and now marketed under the Sauermann brand, have one of the best track records of all specialist products on the market. Tens of thousands of DEBIMO solutions have been sold worldwide and across all sectors and industries, including to some of the most demanding customers out there. These systems are widely recognised by professionals for their consistently accurate performance over billions of hours of operation, especially when coupled with our self-calibrating pressure transmitters.

The numerous ports on DEBIMO blades are distributed using the Log-Chebyshev method, which determines the position of the total and static pressure measurement points. This design provides an extremely accurate reading of the average air flow in pipes of all shapes and sizes.

2 – Rugged build quality

DEBIMO blades can withstand temperatures of up to 210°C, meaning they operate perfectly in even the most extreme conditions. This rugged build quality is made possible by the use of anodised aluminium – a process that creates an oxidised layer on the surface of the metal, making it more resistant to wear and corrosion while preserving its non-biotoxic properties.

The DEBIMO blades can even be coated with ethylene chlorotrifluoroethylene (ECTFE), a thermoplastic film that provides additional protection against particularly corrosive chemicals.

3 - Non-disruptive measurement

With their wing-shaped design, DEBIMO blades cause almost zero pressure drop (less than 3%) and help to reduce turbulence within the system. And since the blades don’t resist the air flow in the pipes, there’s no falsification of the resulting readings. Compared with other, more intrusive options, the DEBIMO solution, therefore, saves energy and keeps the ventilation system balanced.

4 - Custom-made for versatility

Sauermann custom-manufactures DEBIMO blades to the required specifications, meaning they’re compatible with pipes and ducts of all shapes and sizes, from 100 mm to 3,000 mm.

And because they’re rugged, reliable and non-disruptive, these blades are suitable for all types of air flow across all sectors – even the most critical applications such as cleanroom ventilation systems, smoke extraction systems, climate control engineering, and the chemical, pharmaceutical and nuclear industries.

5 – Flexible configuration options

DEBIMO blades are suited to a wide range of monitoring configurations and can be coupled with any type of differential pressure measurement instrument, including our classic CP 210, C 310 and CA 310 transmitters (the blades are ideal with our class 310 devices), as well as our liquid column manometers, which don’t require a power supply. With the right configuration for every circumstance, this solution covers the full range of industrial applications.

6 – Air flow measurement out of the box

The DEBIMO measurement solution requires no additional configuration. Once coupled with the blades, the system displays and/or transmits accurate, internally calculated air flow measurements directly. And because the pipe dimensions are configured in the measurement instrument, there’s no need to make any further adjustments inside the computerised ventilation control system.

Add new comment