Maximing Boiler Performance: Monitoring Unburned Fuel to increase Maintenance Efficiency and Safety

Combustion and the Significance of Unburned Fuel

Combustion takes place when fuel reacts with oxygen to produce energy in the form of heat. The energy generated when fuel is burned is used in the operation of a variety of equipment, including boilers, furnaces, kilns, and engines. In addition to heat, CO (carbon monoxide), CO2 (carbon dioxide) and H2O (water) are created as byproducts of the chemical reaction.

Optimal combustion occurs when energy from the burning of fuels is harnessed in the most efficient way possible through limited heat loss and complete fuel consumption. However, inefficient and potentially unsafe combustion can occur when conditions within a burner/combustion system are below optimal due to normal wear and tear resulting from boiler age or general malfunction, causing the direct release of unburned fuel (hydrocarbons) such as natural gas, methane, propane, etc as a byproduct. Emissions of unburned fuel in combustion indicate revenue loss and a potential serious threat to safety.

Why Monitor Hydrocarbons?

Hydrocarbon emissions are an important indicator in determining the overall quality of combustion and whether a system is safe or in need of immediate maintenance as seen in the following conditions: perfect combustion, good combustion, and unsafe combustion.

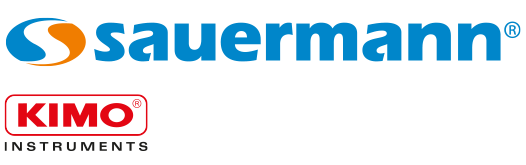

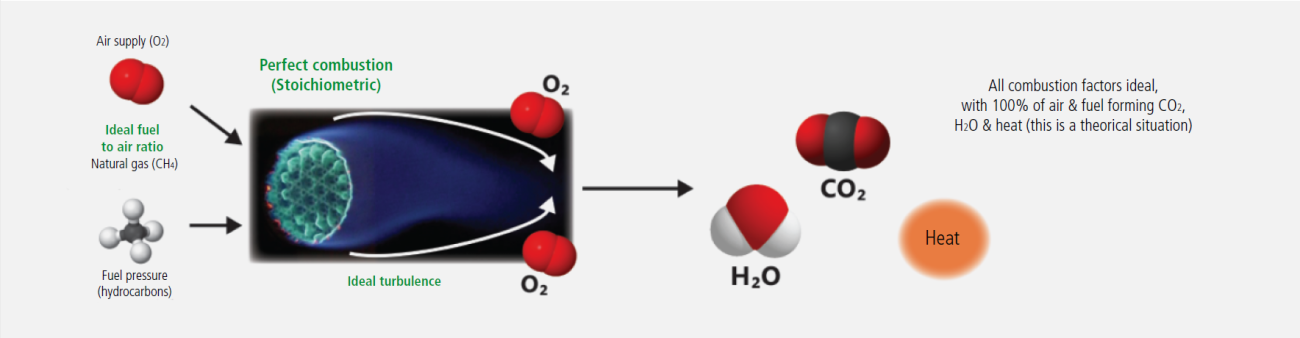

Perfect (Stoichiometric) Combustion

Perfect Combustion occurs when the ideal fuel-to-air ratio is provided within a system, with the perfect residence time and turbulence producing no losses and extracting all of the energy from the fuel. In reality, perfect combustion is theoretical and unattainable due to a variety of factors making 100% efficiency impossible.

Although perfect combustion is unattainable, it is useful to understand the conditions under which it would occur in order to understand combustion systems operating in the field. For perfect combustion to occur, the following factors must be achieved.

Combustion factors in Perfect Combustion:

• Gas pressure/Flow of Fuel is ideal and constant for the load targeted (Ideal fuel to air ratio)

• A perfectly designed Burner and combustion process is in mint condition

• Fuel Characteristics are constant, not varied

• Turbulence is optimal

• Boiler draft is ideal

Assuming these ideal parameters, oxygen (O2) and fuel are introduced to a perfectly running burner exhibiting correct turbulence and immersed in the ideal level of oxygen. The air and fuel consumption are 100% efficient and form CO2, H2O and heat with no additional by products.

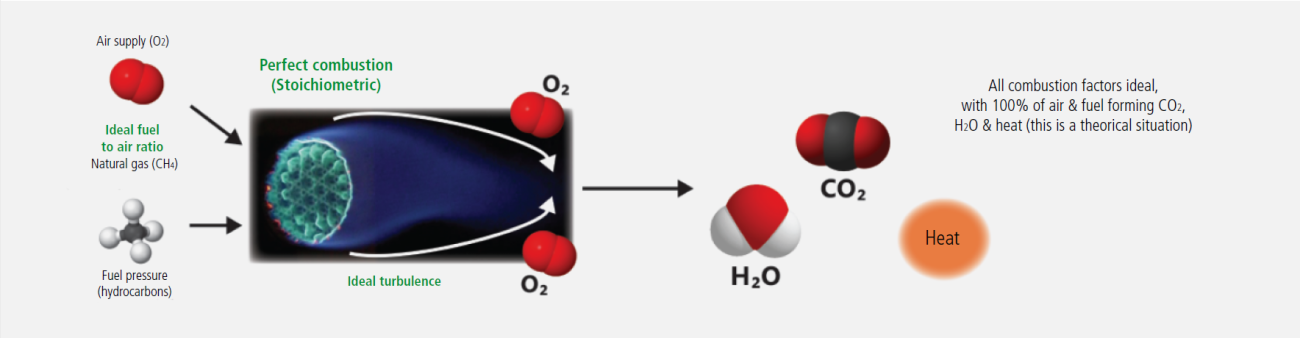

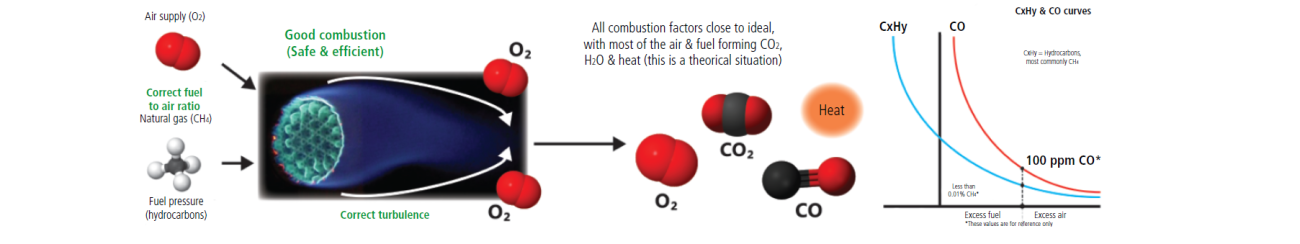

Good (Safe and Efficient) Combustion

Good combustion occurs when all combustion factors are close to ideal allowing for realistically optimal combustion efficiency.

Combustion factors in Good Combustion:

• Gas pressure/Flow of Fuel is relatively constant (Correct fuel to air ratio)

• Burner is in good condition as designed by the manufacturer

• Fuel Characteristics are relatively constant

• Turbulence close to optimal

• Boiler draft is close to optimal

In this condition, air and fuel combine to form water (H2O), carbon dioxide (CO2) and heat with carbon monoxide (CO) emissions of less than 100 ppm. Little to no hydrocarbons are emitted as the system utilises close to 100% of fuel where both combustion efficiency and maintenance efficiency are maximised.

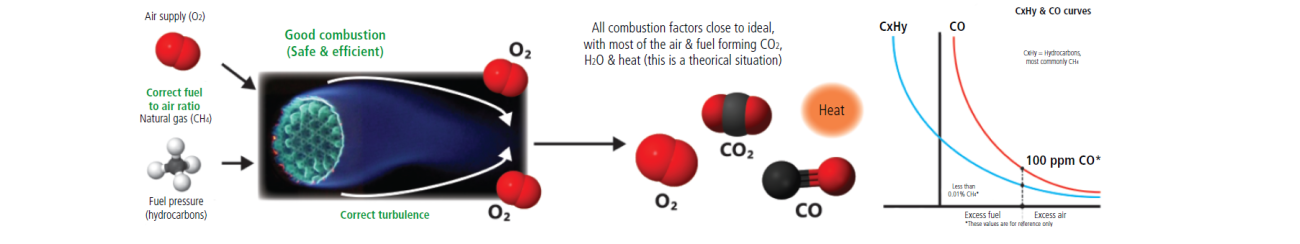

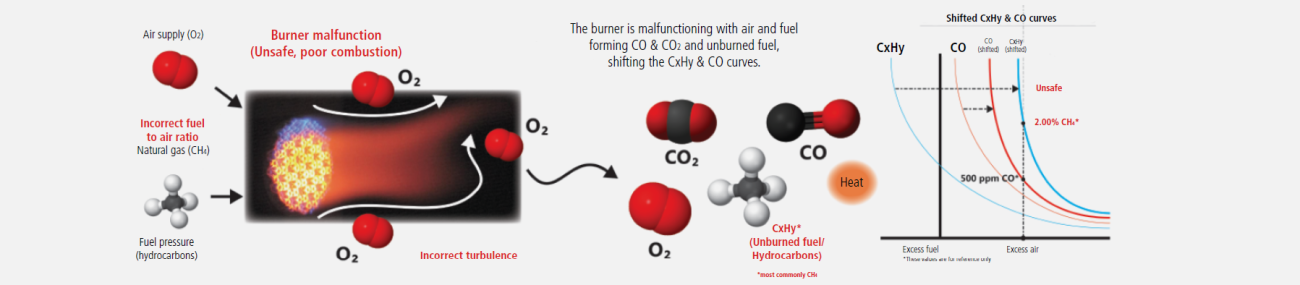

Unsafe/Poor Combustion

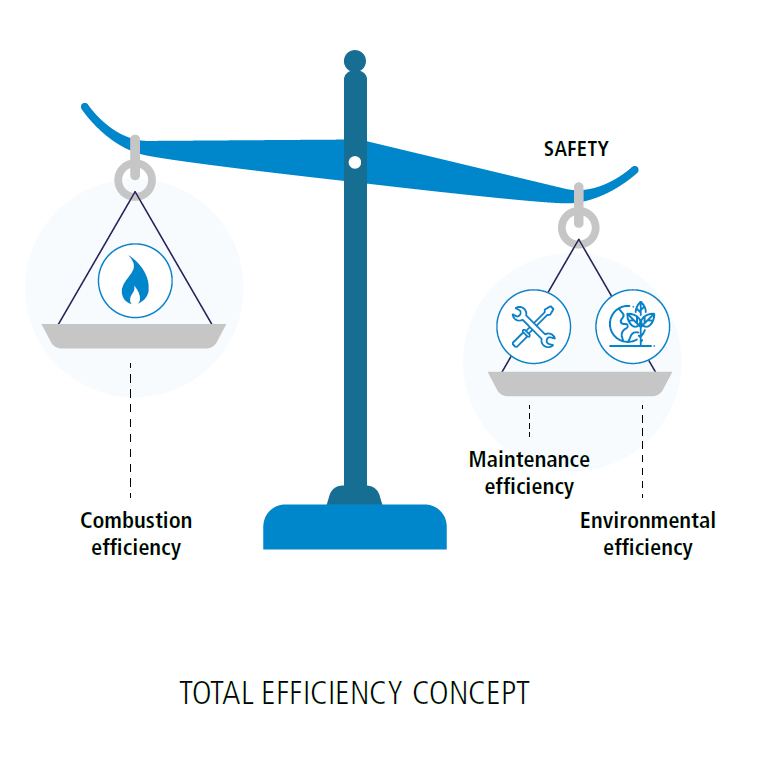

Unsafe or poor combustion occurs when there is a decrease in maintenance efficiency in the form of wear and tear and/or malfunction within one or multiple aspects of a system leading to loss of energy, unburned fuel and excessive emissions. In this condition, unburned fuel/hydrocarbons (CxHy) are emitted indicating that the burner is inefficient, potentially unsafe, and in need of immediate inspection & maintenance. In summary, there is a signicant reduction of both combustion efficiency and maintenance efficiency.

Combustion factors in Unsafe/Poor Combustion:

• Gas pressure/Flow of Fuel is unsteady (Incorrect fuel to air ratio)

• Burner is defective

• Fuel Characteristics are inconsistent

• Inadequate turbulence and incorrect fuel air mixing

• Boiler draft is not ideal

In this condition, air and fuel mix to form water (H2O), carbon dioxide (CO2), and heat with additional emissions of carbon monoxide (CO2) greater than 100 ppm and signicant hydrocarbons (CxHy) in the form of unburned fuel.

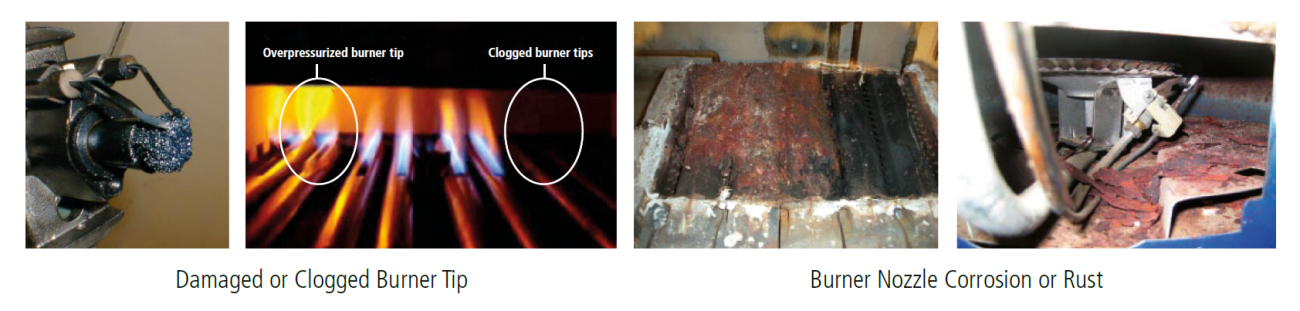

Examples of Unsafe Combustion

Maximising Combustion: Monitoring Maintenance Efficiency and Safety

Maximum Maintenance Efficiency is defined as the performance of a combustion process that is in mint condition as per the manufacturer’s design and burning with good combustion. Safety is closely linked to maintenance efficiency and is of concern in any type of combustion process. As burner components and other combustion process parts get older, deteriorate, corrode or break the maintenance efficiency will decrease and may result in dangerous conditions. To ensure that a boiler’s maintenance efficiency is near optimal and that the system is safe, it is important to:

1. Perform the maintenance and relevant visual inspections recommended by the boiler & burner manufacturers

2. Closely monitor the gases associated with combustion including the amount of excess O2 needed to achieve good combustion and emissions such as carbon monoxide (CO) and any unburned fuel, or hydrocarbons (CxHy) in the flue gas

Monitoring of combustion efficiency is standard practice among HVAC professionals. However, assessing and controlling for the Maintenance Efficiency and Safety of a system, two parameters that directly impact overall boiler performance, is an often overlooked, and potentially dangerous omission. Instrumentation designed to address these two important parameters is imperative for the professional aiming to provide better and expanded service capabilities to customers interested in understanding the overall efficiency, cost, safety and productivity of their combustion systems.

Maintenance Efficiency and Safety Monitoring Solution: Sauermann Si-CA 230

Sauermann provides the ability to quickly and easily assess BOTH the combustion efficiency and the maintenance efficiency & safety with our Si-CA 230 hand-held combustion gas analyser. This specialised combustion flue gas, emissions, and safety

analyser can measure gases and calculate parameters relevant to combustion efficiency including O2, CO, NOx, CO2, combustion efficiency, excess air & lambda for air-to-fuel ratio, flue gas & differential temperature, gas pressure, and draft. It can also provide proper maintenance efficiency & safety analysis by directly measuring the unburned fuel (CxHy Hydrocarbons) in the exhaust stack simultaneously with all of the other combustion parameters. The Si-CA 230 can also perform ambient CO monitoring and heat exchanger integrity testing to help ensure a safe environment around the combustion equipment.

This unique gas analyser includes the Sauermann Combustion app and PC software with, wireless connection printing for on-site reporting and record keeping, robust unbreakable metal connections, field replaceable sensors, and easy-to-use functionality backed up by Sauermann’s unmatched technical and customer support.