Si-30 Detect+ Case study - Atelier de Valérie (Chocolaterie)

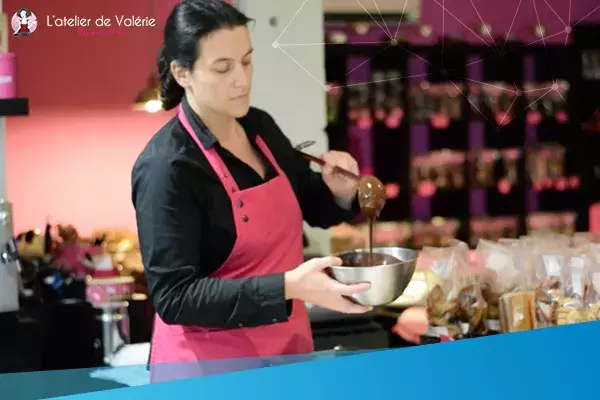

Located in Batz-sur-Mer, western France, L’Atelier de Valérie is a manufacturer and retailer of regional artisan-made chocolates and pastries. Founded in 2012, Valérie Cottet-Emard, the proprietor, along with her team, have worked hard to make this business a success. Valérie manages the day-to-day operations ranging from making chocolates to storing and arranging them for display. She hails from the same region and has decades of experience in this profession.

Ensuring the chocolates and pastries have the highest quality requires long term dedication and attention to fine detail, including environmental conditions. For example, room temperature should remain constant. To meet this requirement, four wall mounted air conditioners were installed across the manufacturing and shop areas. Due to the climatic conditions in the West coast of France, air conditioners run 24/7 throughout the year.

Since the air conditioners are always on, the condensate discharge is continuous, and gravity drains do not work. Therefore, Sauermann Si-30 mini condensate removal pumps with Si-2958 detection units were installed to evacuate the condensate.

The Challenge

In most cases, a regular Si-30 mini-condensate removal pump could be used to discharge the condensate, but not in this case. Why? Because preparing chocolates and pastries involves the heavy use of loose density particles, including a variety of colourants, flour, and cake sprays. These particles enter the cooling system and impact the condensation and condensate evacuation process. A thick and sticky substance known as biofilm is formed just after the condensation and discharged via the condensate tube. This formation makes it hard for the detection unit to work properly, thus creating the need for frequent cleaning and maintenance.

Because of these extreme conditions, Valérie was forced to get servicing done every two months instead of on a yearly basis, and this resulted in huge maintenance costs and wasted time.

The Solution

While not initially looking for a solution, an HVAC technician regularly cleaned Valerie`s pump every two months or so. After a period, he realised the reoccurring problem should ideally be solved by the pump manufacturing company itself. So, the technician reached out to a distributor, and the distributor notified Sauermann. At the same time, Sauermann was already working on developing a condensate pump with a special detection unit.

Through collaboration between the technician, Valérie, and Maurice (the Sauermann regional sales expert), a solution for this problem was tested. An electronic detection unit was integrated to the pump, and field tests were conducted for a few months with these combined technologies. The result was the Si-30 Detect+.

The Benefits

After installing the Sauermann Si-30 Detect+, there have not been any condensate blockage incidents, and HVAC maintenance is done once a year instead of every two months. This has helped Valérie decrease maintenance costs fivefold and allowed her to concentrate on expanding her business.

Add new comment