Flexibility and Versatility in a Portable Emissions Analyzer

Issue: Fixed CEMS (Continuous Emissions Monitors)

Only Measure at One Location

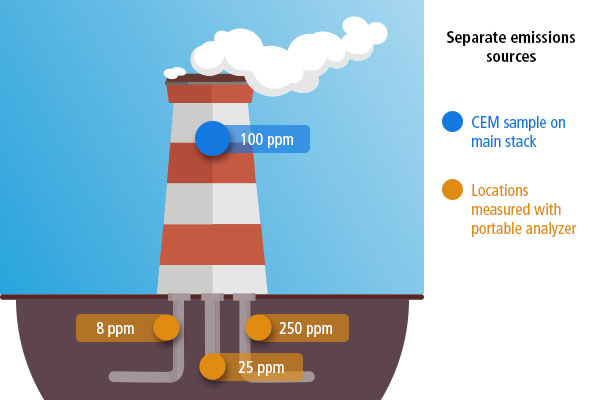

CEMS are fixed units that typically only measure from one sample location which is usually on a main centralized stack. This main stack is often fed by several separate emissions sources throughout the plant such as boilers, heaters, engines, ovens, and furnaces. If the CEM is measuring emissions that are higher than the regulated or permitted limits, it can be difficult to determine the source of the high emissions which could be from any or several of the separate sources that feed into the main stack.

Benefits: Measure with a Portable Emissions Analyzer

The customer can measure from any of the smaller stacks that feed into a main stack or from any emissions source throughout the plant with a portable emissions analyzer. A portable analyzer provides more flexibility and versatility than a CEM in terms of the multiple locations it can be used throughout the plant and how it can measure different emissions sources. Using a portable emissions analyzer can help to quickly and more precisely determine sources of high emissions and inefficient or unsafe equipment performance.

Instrument Solution: Si-CA 230 Hand-Held Emissions Analyzer

The Si-CA 230 hand-held industrial combustion gas and emissions analyzer is a light, compact, durable unit that can easily be used for accurate emissions measurements throughout a plant. The Si-CA 230 can have a maximum of six gas sensor (O2, CO, NO, NO2, SO2, CxHy, H2S) and includes a mobile phone app and PC software with wireless communications.