Indoor air quality matters in data centres too!

The number of data centres is increasing at an unprecedented rate as the world shifts to a digital-led economy. These server farms are also becoming ever bigger in size in order to keep up with the rapidly growing volume of data that needs to be stored, transferred and shared online. As the nerve centres of the web, data centres consume vast quantities of energy. They also generate a huge amount of heat, which can cause damage to components if left unchecked.

Overcoming this challenge requires extremely powerful HVAC systems – so powerful in fact that, on average, air-conditioning systems account for 35% of a data centre’s total electricity consumption. This staggering figure reveals what an important role indoor air plays inside these facilities, in terms of both temperature and humidity.

Living organisms require certain conditions to survive. The same goes for servers: the indoor air quality, or IAQ, has to be just right to keep them healthy and performing reliably. And maintaining this IAQ within the right range requires advanced HVAC technology and monitoring equipment embedded within the system itself.

What measurement instruments are needed for data centres?

In a server room, even the slightest deviation from the prescribed climate conditions can cause millions of dollars’ worth of damage. Overheating can destroy delicate and costly components such as the CPU, GPU and hard drives. In the worst cases, it can even start a fire. And even minor technical problems lead to downtime, which erodes both the centre’s profitability and customers’ trust.

For these reasons, data centres need to be kept under close watch around the clock – a process that requires state-of-the-art HVAC measurement instruments. So here, we look at the devices involved and explain what parameters need to be measured:

- Air flow rate and velocity:

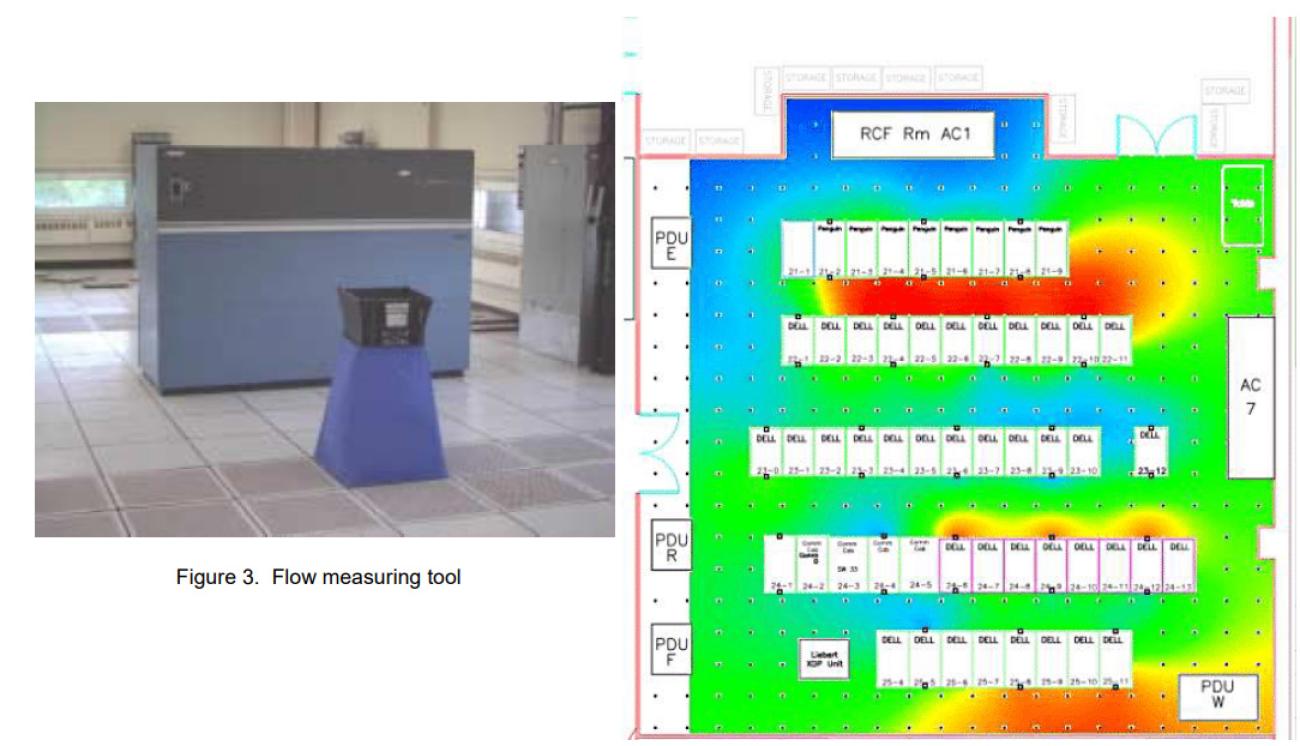

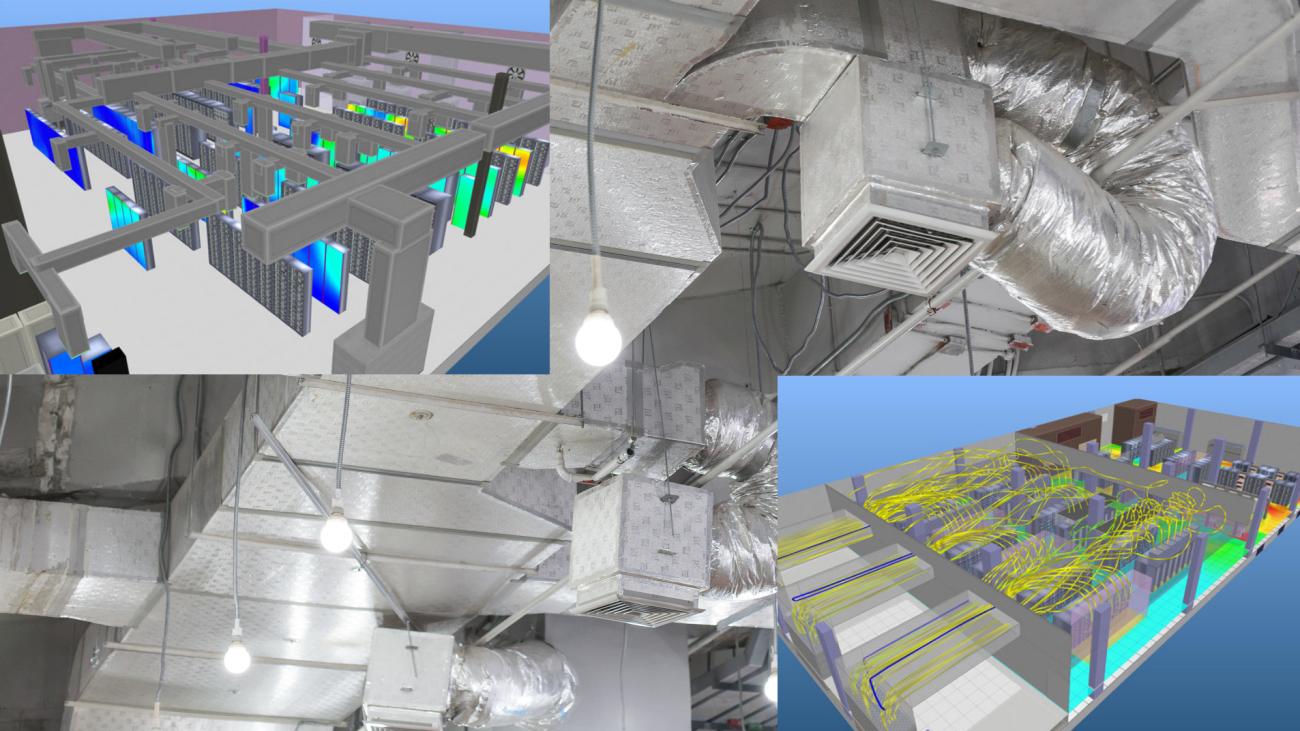

- These parameters are measured throughout a data centre. The aim is to make sure that air continues to circulate properly through the facility’s ventilation system, as well as in the server room itself, through the cool air inlets and hot air outlets, and inside the rack units.

- Various instruments can be used to measure these parameters. In most cases, permanent monitoring is performed by connected fixed transmitters, some of which are multifunction, and include a hotwire thermo-anemometer. A pressure sensor (manometer) coupled to a Pitot tube or to DEBIMO blades is another ultra-reliable solution for ventilation system pipes.

- For one-off measurements taken during system health checks, engineers use portable instruments such as hotwire or vane thermo-anemometers and multifunction devices like the AMI 310. And perhaps the most important of all is the DBM 620 air flow meter, which is essential for calculating the actual air change rate in system-critical locations.

- Temperature, humidity and dew point:

- Monitoring temperature is, of course, vital for preventing damage to server equipment. But it’s also a helpful way to calculate the real-world efficiency of the cooling system, by comparing its performance against how much electricity it uses. Various options are available, from multifunction fixed-position transmitters to data loggers like those in the TrackLog range, which are designed for use in even the most demanding conditions, including inside electrical and UPS rooms.

- As we explain in our blog article on actively cooled electric battery clusters, hotwire thermo-anemometers are especially useful because as well as providing accurate temperature readings, they also measure air velocity (and, by extension, air flow rate if required).

- Thermo-hygrometers remain the best type of device for this particular application: because they measure both temperature and hygrometry (relative humidity), they can be used to calculate the dew point. These parameters are vitally important for data centres, where the air has to be humidified to keep its moisture content within the optimal range. If the air is too dry, it can cause electrostatic discharge. And if it’s too humid, oxidation can occur, shortening the lifespan of system components.

- Thermocouple thermometers are typically used to measure the critical temperatures of the hottest server components: the power supply units, processors, hard drives and heat sinks. They’re also used to monitor superheat and sub-cooling of the refrigerant circuit in Computer Room Air Conditioning (CRAC) units to make sure the units are operating correctly.

- Pressure and differential pressure:

- As we’ve already explained, pressure sensors (manometers) are coupled with Pitot tubes or DEBIMO blades to measure air flow rate. But they have other uses too, such as inside the server room itself, where there’s a hermetic seal between the cold aisle (the cold air inlet at the front of the servers) and the hot aisle (the hot air outlet). In this type of configuration, it’s important to check that the pressure in the cold aisle is greater than in the hot aisle, which helps to optimise the flow of cooled air. Our CPE 310 instrument, for instance, is used for precisely this purpose in many labs and hospitals, while numerous data centres have installed our C 310 device to measure pressure alongside temperature and humidity.

- Data centre operators also need to monitor the differential pressure at air filters, so they can check for fouling and schedule filter changes while keeping downtime to a minimum. These air filters play a vital role in preventing the build-up of dust which, if left unchecked, can cause electrostatic discharges. And they’re especially important for data centres located in countries with colder climates, which sometimes use Computer Room Air Handler (CRAH) systems instead of conventional air-conditioning units. These systems, which consume less energy, keep the system components cool by blowing in cold air (and using cold water) from outside. Here, the measurement process is similar to that used in face mask tests.

Condensate removal pumps: a common feature of data centres

As we explained earlier, the air inside a server room needs to be kept at constant moisture content: the latest guidance from ASHRAE recommends relative humidity of 55-69% at a temperature of 18-27°C and with a dew point of 15°C. When this air passes through a CRAC unit, some of this moisture condenses. This forms a build-up of condensate within the evaporator, which needs to be removed. Where removing the condensate by gravity isn’t an option, the data centre will need to install a reliable, high-capacity condensate removal pump to prevent leaks and overflows. Our Si-82, Si-1805 and Si-1820 pumps are designed precisely for this purpose, depending on the power of the cooling system.

----------------

Learn more:

- Comprehensive review of data centre cooling technology

- ASHRAE Data Center Standard

- Data centre humidification

- A look at data centre cooling technologies (CRAC & CRAH)

- Explainer video focusing on data centre cooling systems and air management strategies

- Our recent blog article on using air flow meters to monitor data centre health

Picture credits: Upsite - TileFlow - ResearchGate

Add new comment