How to reduce the noise from a mini condensate removal pump

As every industry professional knows, air conditioning units produce condensation when cooling the air inside a room. If the resulting liquid, known as condensate, can’t be drained away by gravity alone, it has to be removed using a small pump instead. These mini pumps can generate noise, which can inconvenience the occupants of an otherwise quiet room.

According to laboratory tests conducted to ISO 3744, Sauermann’s mini-pumps are among the quietest models on the market. For instance, the Si-30 pump is the epitome of discretion, producing just 20 dB(A) in operation – a level of sound pressure that’s barely detectable to the human ear. But this measurement doesn’t tell the whole story...

Intrinsic noise and vibrations

In order to measure – and, crucially, compare – the noise generated by piston pumps, it’s important to use a detailed ISO standard that provides a method for measuring and calculating the final result.

| Mini pump | Si-30 | Si-10 Univers’L | Si-27 | Si-20 | Si-33 |

|---|---|---|---|---|---|

| Measurement (according to ISO 3744) |

20 db(A) | 22 dB(A) | 20 db(A) | 22 dB(A) | 34 db(A) |

However, these acoustic tests are performed in a controlled lab environment. And they only measure the sound generated by the pump, which is suspended during the test and, therefore, isolated from its surroundings. Consequently, these lab measurements make no allowance for the vibration of objects and structures that the pump touches or is affixed to in real-world situations.

These vibrations travel from the pump to its bracket, to its power supply cable, and especially to the flexible PVC pipes through which the condensate drains away. If these components also start to vibrate, they’ll inevitably create sound waves – in other words, noise. And sometimes, if these materials vibrate at just the right resonant frequency, they can become even louder. When it comes to the noise generated by condensate removal pumps in air conditioning units, this is where the crux of the problem lies.

Keeping condensate removal pipes quiet

As has become clear, it’s vital to think carefully about the installation of the condensate removal system as a whole. Preventing even the slightest vibration from travelling through the system is the number-one priority.

It’s also important to remember than some pumps can produce hydraulic noise. This is caused by the suction of water, especially when there are air bubbles in the liquid. Sauermann’s piston pumps feature a detection system that’s designed to eliminate this problem because it prevents the pump from sucking air at the same time as condensate. They also come with a second system – a Y-shaped Drain Safe Device that means the pump will never suck air when it’s started up.

So here are some top tips for keeping your air conditioning unit running as quietly as possible:

Initial comments:

These rules don’t necessarily apply to open-plan offices that are occupied during the daytime, since natural noise levels will largely drown out the sound of the condensate removal system. That’s why the Delta Pack and Omega Pack are ideal for these environments: they’re visually appealing, incredibly convenient to install and include various anti-vibration components.

| Best option | Mid-range option | Worst option | |

|---|---|---|---|

| Locating the pump | Behind the wall where the split system is located, above the ceiling or in the attic space (but not outside the building!). | In the false ceiling inside the room. | Near the split system in a quiet room. |

| Mounting the pump | Hang the pump using the anti-vibration mounting bracket. | Affix the pump to a rigid supporting structure using the anti-vibration mounting bracket, ideally on the insulating foam surrounding the refrigeration circuit. | Affix the pump to plasterboard, plastic trunking, a metal pipe or similar. Affix the pump without its anti-vibration mounting bracket. |

| Managing the power supply cable and the flexible PVC tubing | Wrap the cable and tubing in insulating foam. Keep the tubing well away from other surfaces. | Attach the cable and tubing firmly to a rigid, solid surface. | Leave the cable and tubing exposed (without insulation and trunking) and place them near a wall or ceiling. |

See some of these tips in our mounting video guide:

Noise and silence: from theory to practice

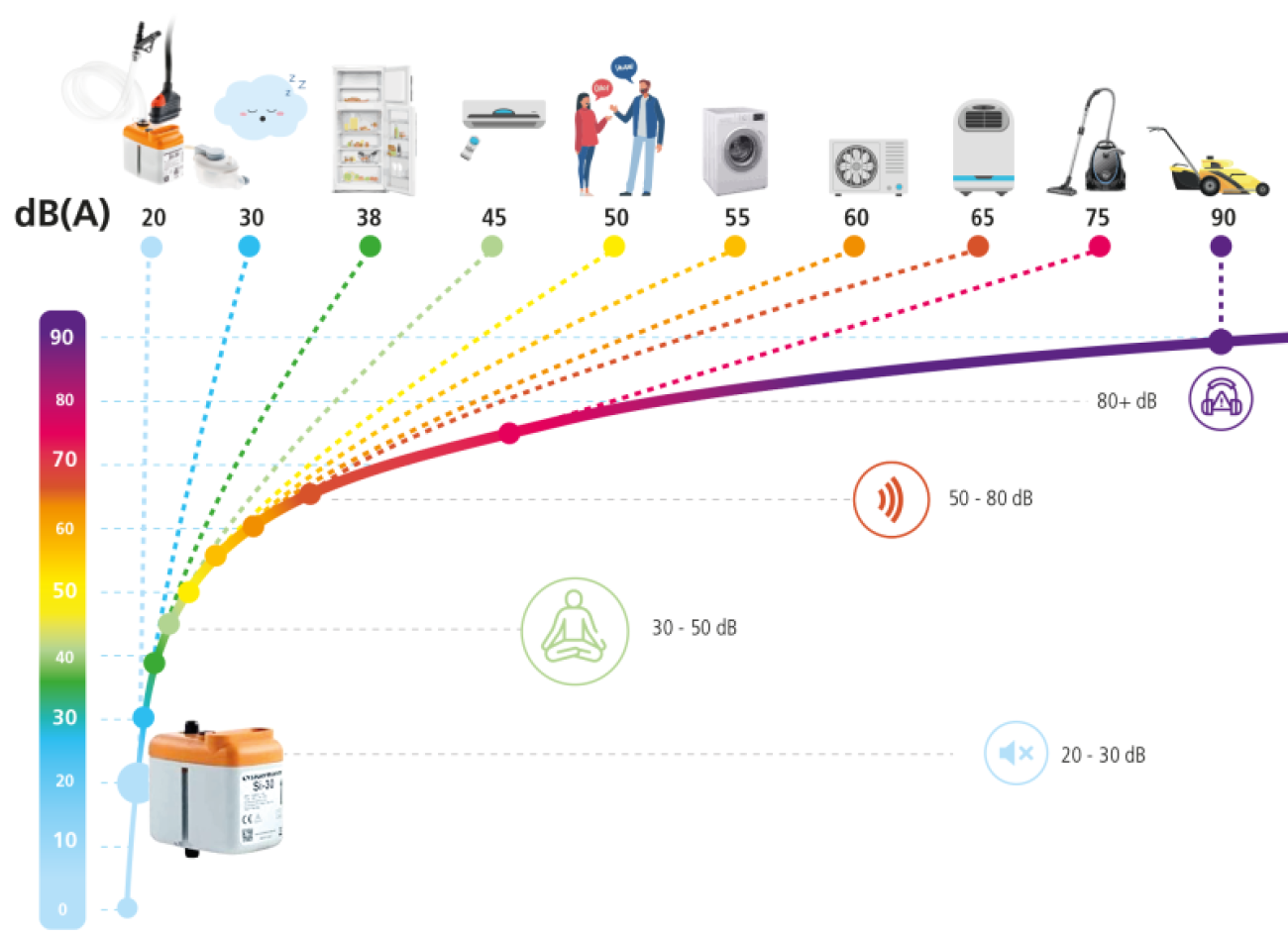

Sound is measured in a unit known as decibels. For instance, our Si-30 pump produces a sound measured at 20 dB(A). But sound is a complex and subjective phenomenon. So here’s a brief explanation of how it works.

As a pressure wave moves through the air at a given frequency, our ear drums perceive this variation in pressure as sound. The corresponding unit, the decibel, therefore has the unenviable task of representing both acoustic pressure and a subjective auditory sensation.

The pressure range to which the human ear is sensitive is vast, ranging from 0.000002 to 200 Pascals. That’s why the decibel is a logarithmic unit – because it allows this immense range to be compressed into a narrower band of values that our brains can compute.

But it’s also important to remember that the decibel isn’t an absolute value. It’s a measure of relative loudness, which is why a statement such as “two cars are twice as loud as one car” doesn’t really hold true. And because this scale is relative, when we perceive a sound that to our ear is twice as loud as another sound, that doesn’t mean it’s double the value in terms of decibels. In fact, a doubling in loudness translates to an increase of 10 dB.

| Sound source | dB(A) value | Sensation |

|---|---|---|

| Si-30 mini-pump alone* | 20 | Almost inaudible |

| Extremely quiet room | 30 | |

| Refrigerator | 38 | Comfortable |

| Gaming computer | 42 | |

| Air conditioning unit (indoors) | 45 | |

| Normal conversation | 50 | |

| Washing machine | 55 | Tiring |

| Air conditioning unit (outdoors) | 60 | |

| Self-contained air conditioning unit | 65 | |

| Vacuum cleaner | 75 | |

| Lawn mower | 90 | Uncomfortable |

| Nightclub | 100 | |

| Concert | 110 | Dangerous |

| Shotgun | 120 | |

| Rocket engine | 180 |

*ISO measurement: pump suspended and unmounted

Based on this scale, to a healthy ear, a vacuum cleaner is 32 times louder than an Si-30 pump (a difference of 5x10 decibels, or 25 = 2x2x2x2x2 = 32). The chart below provides an easy-to-understand visual representation of how sound levels increase, as measured in decibels. This is known as an exponential curve, whereby loudness increases with every increment of 10 dB, best representing how the human ear perceives sound. Looking at this curve, it’s easy to imagine how painful the 180 dB sound generated by a rocket engine would be!

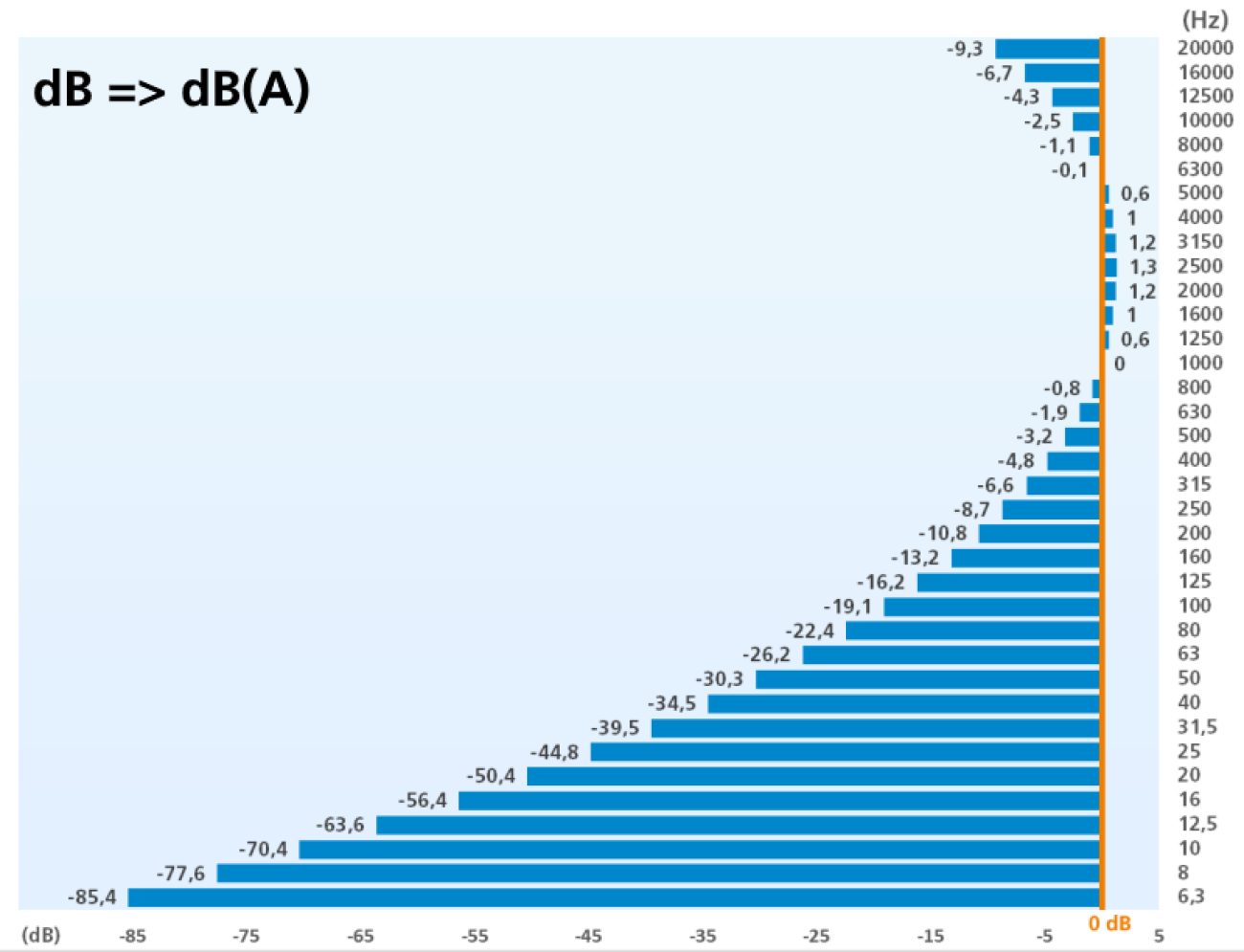

Let’s go back to our Si-30 pump, which has a sound rating of 20 dB(A). You may be wondering what the “(A)” means. Let’s explain: when measuring a value in decibels, it’s important to remember that the human ear perceives sounds at some frequencies better than others. In order to more accurately reflect how we perceive sound, we use an aggregated (“A-weighted”) system based on the following pre-defined values:

The dB(A) value – generally lower than the absolute value – is obtained after these weightings have been applied, more faithfully representing how our ears experience a given sound.

There’s one final, crucial detail that can’t be overlooked: the distance that a sound travels before it reaches our ears. Sound waves lose energy as they travel, which is why distance from the source is a key parameter in standards for measuring sound levels. Most standards apply a uniform distance of one metre. But once again, it’s important to think in relative terms: in air and without obstacles, sound pressure decreases by 6 dB for each doubling of distance from a point source. What’s more, this value can vary depending on the type of sound in question, whether the sound waves bounce off the corner of a wall, and many other factors.

In summary, acoustics is a complex science influenced by myriad environmental variables and the subjectivity of human perception.

After all, sound is in the ear of the beholder!

Add new comment