[How to] How and why should you clean the condensate removal pump in your air conditioning unit?

Indoor air conditioning units tend to be equipped with a mini condensate removal pump, which removes the liquid formed by condensation in the heat exchanger. These pumps naturally foul over time. But why?

Biofilm: a universal problem

Biofilm is enemy number one – and the leading cause of fouling in a condensate removal pump. No matter what the conditions, it’s impossible to avoid the build-up of biofilm. It forms when bacteria act in symbiosis to create the environmental conditions they need to multiply. This so-called “biological cocoon” consists of a thick, multi-cell layer that’s viscous when wet and sticky when dry.

Biofilm might be the main culprit, but it’s important not to overlook other causes, depending on where the unit is situated:

-

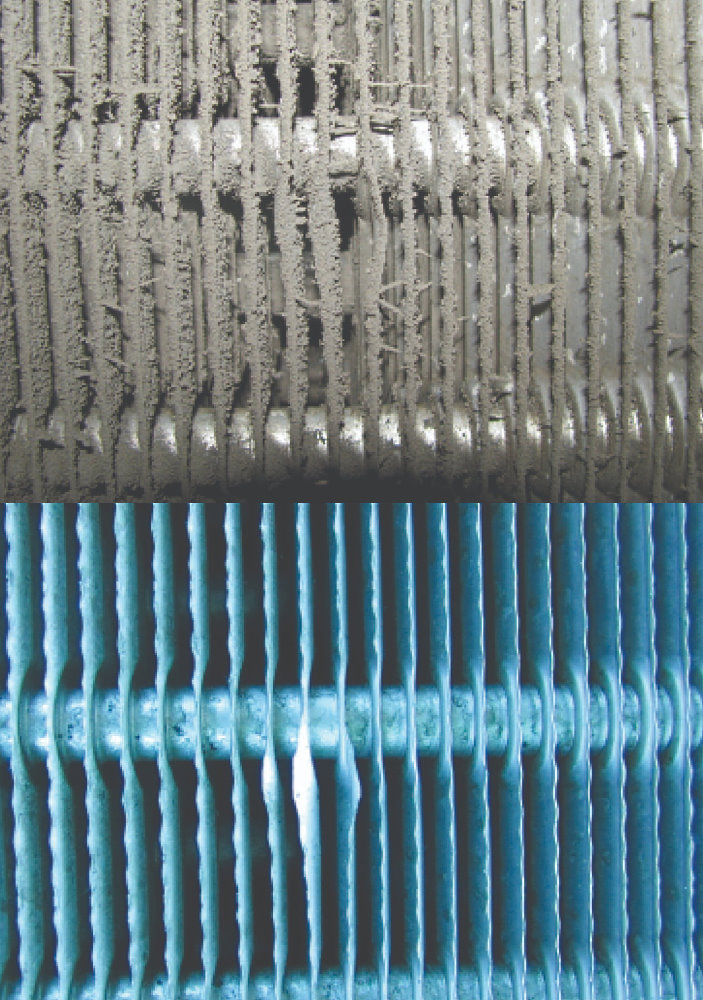

Dust and particles suspended in the air, which end up being deposited on the heat exchanger.

-

Some aerosols and other types of lacquer that dissipate in the air (such as at hair salons).

-

Cellulose (paper) dust, which is present in large amounts in libraries and bookshops.

-

Tobacco smoke (micro-particles build up in a thick layer).

-

Smoke from cooking oils and fats, especially in open-plan kitchen spaces (see our example from a chocolate factory).

The above list isn’t exhaustive, but it gives an idea of the sheer range of particles that are sucked into an air conditioning unit during cooling.

Protect the detection unit!

The main reason for maintaining a pump is to make sure that the level detection unit, located in the tank, is working as it should, so it can control the suction correctly.

Some conventional detection units, such as float-type systems, operate mechanically and are especially sensitive to fouling. The float can become stuck to biofilm at the bottom of the tank, which has dried out after spending the winter in heating mode – and therefore producing no condensation. Aerosols, lacquers and smoke from oils and fats can have the same effect. The unit can also be prevented from rising by accumulated dust and particles. And if the detection unit gets stuck, the pump doesn’t come on – and that’s when leaks can start!

Cleaning and maintaining a condensate removal pump: our tips

Each year, before summer, you need to check that your air conditioning unit is in good working order. Focus specifically on the mini condensate removal pump, which can even foul over winter when the unit is in heating mode and the pump is out of use.

-

It’s often tricky to access a mini condensate pump, and even harder to get to the built-in detection unit, which is buried deep inside the air conditioning unit. It involves detaching the unit from its wall mount, then removing the detection unit from the pump. This is a job for a professional.

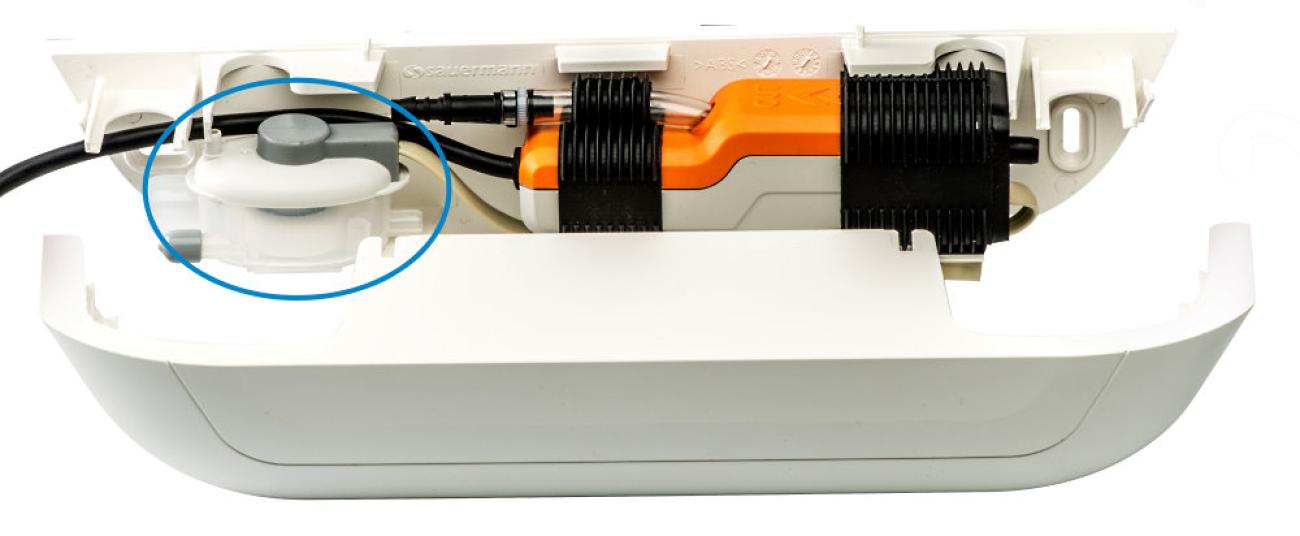

Our Delta Pack and Omega Pack solutions make accessing the pump considerably easier, significantly cutting the amount of time HVAC engineers need to spend maintaining the unit. The pump is located off-centre in easy-open trunking, while fouling is quick and easy to spot through the transparent tank.

-

The power supply to the air conditioning unit should be switched off before performing maintenance, but keep the power to the pump switched on to test its function.

-

To check whether the pump is working properly (and the detection unit in particular), use a burette to distribute water evenly across the surface of the heat exchanger and then into the tray below. If the unit has a transparent tank, you can empty it to observe the pump as it functions. If not, you can listen carefully to the sound it makes as it fires up. If you spot a leak, this suggests that the pump is either excessively fouled or broken.

-

You can buy special pump cleaning products from distributors. If you cannot get hold of a specialist cleaning product, you can use a solution of 5% bleach in water (ideally demineralised). IMPORTANT: Never use petroleum products or solvents such as acetone. These will destroy the parts made from plastic, and especially rubber (pump seals and central mechanism). White vinegar is of limited use because the condensate is mineral-free, meaning that no limescale forms.

-

Next, open the detection unit tank and rinse it using the same liquid (or water) to remove all the particles. Make sure the bottom of the tank isn’t sticky, that the float is clean and free from sticky residue, and that it slides smoothly. The same cleaning and maintenance procedure also applies to capacitive detection systems. Although they don’t contain any sliding mechanical parts, they will still benefit from thorough cleaning!

-

Finally, re-insert the detection unit, and remember to double-check that it’s working correctly by following the guidance in step 3.

Add new comment