The Road to Environmental Efficiency

Why Monitor Nitrogen Oxides (NOx)?

Nitrogen oxides (NOx) are toxic gases common to combustion processes that are highly regulated by state and federal Environmental Protection Agencies (EPA). Exceeding the environmental limit not only compromises worker health and safety, but may require supervisors to shut down a plant and/or pay a fine for noncompliance. Understanding NOx levels and the relationship with other combustion gases such as hydrocarbons (CxHy) in combustion processes will ensure that the right balance is struck among combustion, maintenance, safety and environmental efficiencies. NOx emissions are an important indicator in determining whether a system is in need of adjustment for environmental compliance.

The Interplay Between NOx and Hydrocarbons (CxHy)

Monitoring for all gases involved in combustion, including NOx and CxHy, and understanding their relationship to one another is imperative for supervisors in ensuring that their plant operates efficiently, safely and within environmental limits.

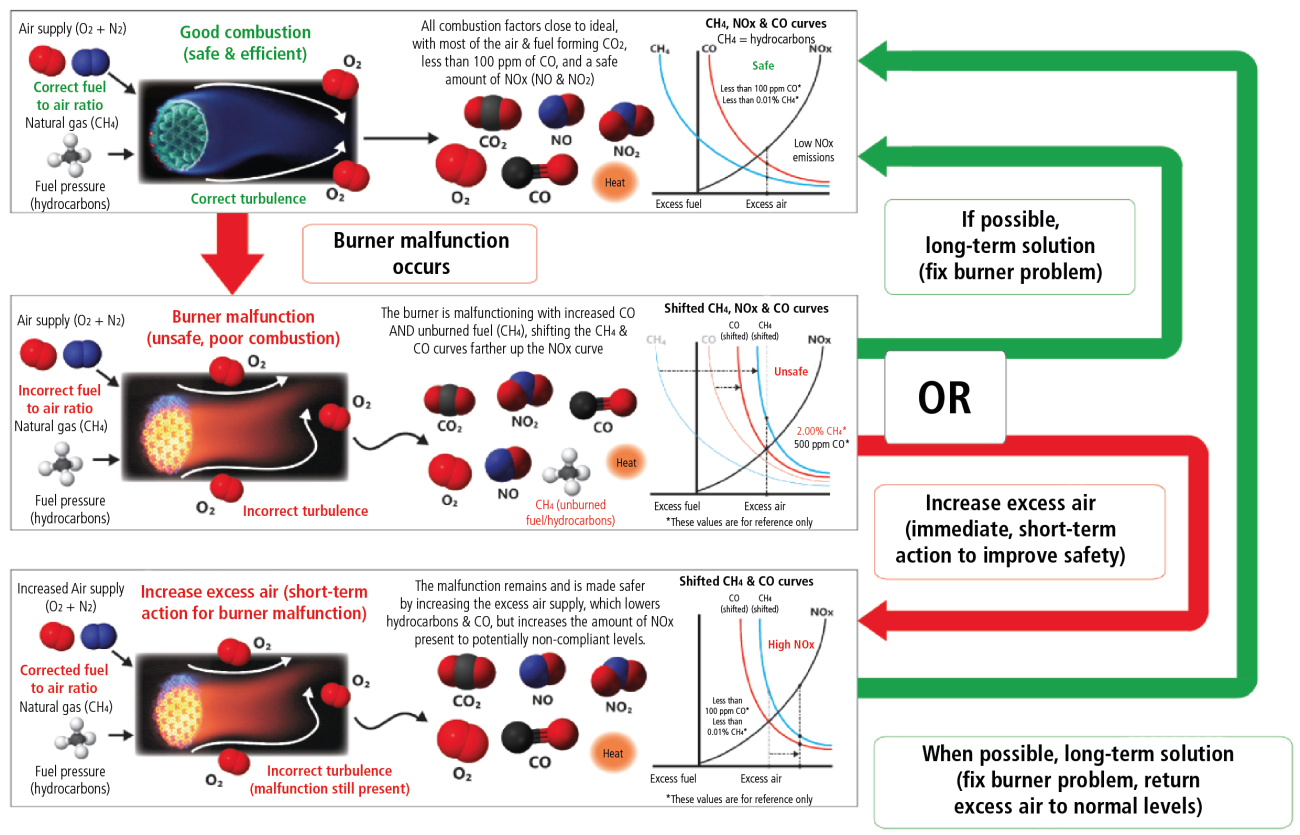

Good Combustion occurs when all combustion factors are close to ideal allowing for optimal combustion efficiency. During Good Combustion, air and fuel combine to form water (H2O), carbon dioxide (CO2) and heat with carbon monoxide (CO) emissions of less than 100 ppm. NOx levels are within EPA established limits and little to no CxHy are emitted as the system utilizes close to 100% of fuel where both combustion efficiency and maintenance efficiency are maximized.

However, in the case of Burner Malfunction, CxHy and CO levels often rise indicating decreased combustion efficiency and overall safety, while increasing cost of production.

A common, short-term solution to this problem is increasing excess air in the combustion system, which corrects the fuel to air ratio and lowers levels of CxHy and CO from unsafe to safe, but also increases NOx levels to levels that are unsafe and often exceeding EPA limits.

Gas Levels in Good Combustion and Solutions for Solving Burner Malfunction

The diagram below highlights the interplay among combustion gases such as CO2, NOx, O2 and CxHy in three different scenarios:

1) When a boiler is undergoing good combustion

2) In the case of burner malfunction

3) During the often used short term solution to solve that burner malfunction of increasing excess air

Maximizing Combustion: Monitoring for Environmental Efficiency

Maximum Environmental Efficiency can be defined as the maximum energy performance of a combustion process that is operating safely while in compliance with federal and state regulations that have been established under the guidelines of the Clean Air Act and the Environmental Protection Agency (EPA). The combustion of fossil fuels releases toxic compounds such as CxHy, CO, and NOx. If gas emissions from combustion processes exceeds federal or state limits, boilers or entire plants can be shut down until compliance is met, highlighting the importance of periodic monitoring and maintenance.

To ensure that a boiler’s environmental efficiency is near optimal and that the system is safe, it is important to:

1) Perform the maintenance and relevant visual inspections recommended by the boiler & burner manufacturers

2) Closely monitor the gases associated with combustion including the amount of excess O2 needed to achieve good combustion and emissions such as CO, CxHy and NOx in the flue gas.

Monitoring of combustion efficiency is standard practice among professionals. However, assessing and controlling for the Environmental Efficiency, along with Maintenance Efficiency and Safety of a system, is an often overlooked, and potentially dangerous omission. Instrumentation designed to address this important parameter is imperative for the professional aiming to ensure the overall efficiency, cost, productivity and environmental compliance of their industrial systems.

Environmental Efficiency Monitoring Solution: Si-CA 230

Sauermann provides the ability to measure & assess BOTH the combustion efficiency and the environmental efficiency easily with our “ALL-IN-ONE” Si-CA 230 hand-held combustion gas & emissions analyzer.

This specialized Combustion Gas, Emissions, and Safety Analyzer measures and calculates the gases and parameters relevant to combustion eciency including O2, CO, CO2, Combustion Efficiency, Losses, Pressure, and Draft. The Si-CA 230 also directly measures NO/NOx and CxHy hydrocarbons for environmental compliance simultaneously with all other parameters. The instrument also provides the user with a variety of other testing capabilities including personal ambient CO safety monitoring, built in pressure manometer, differential temperatures, and more. This unique gas analyzer can have a maximum of six gas sensors and includes a mobile app with remote display & control, touch screen, automatic data logging, CO dilution, report creation & wireless printing for on-site reporting and record keeping, field replaceable pre-calibrated gas sensors, and easy-to-use functionality backed up by Sauermann’s excellent technical and customer support.