Practical applications of combustion gas analysis: versatility in action

Avec l’accumulation des règlementations et des impératifs environnementaux, l’analyse de combustion devient de plus en plus exigeante au fil des années. Les professionnels du secteur couvrent désormais un très large spectre de mesures selon les machines et les secteurs concernés. Cette discipline transverse touche donc plusieurs applications pratiques principales, qui exigent des analyseurs de combustion particulièrement polyvalents.

Energy efficiency: a central concern

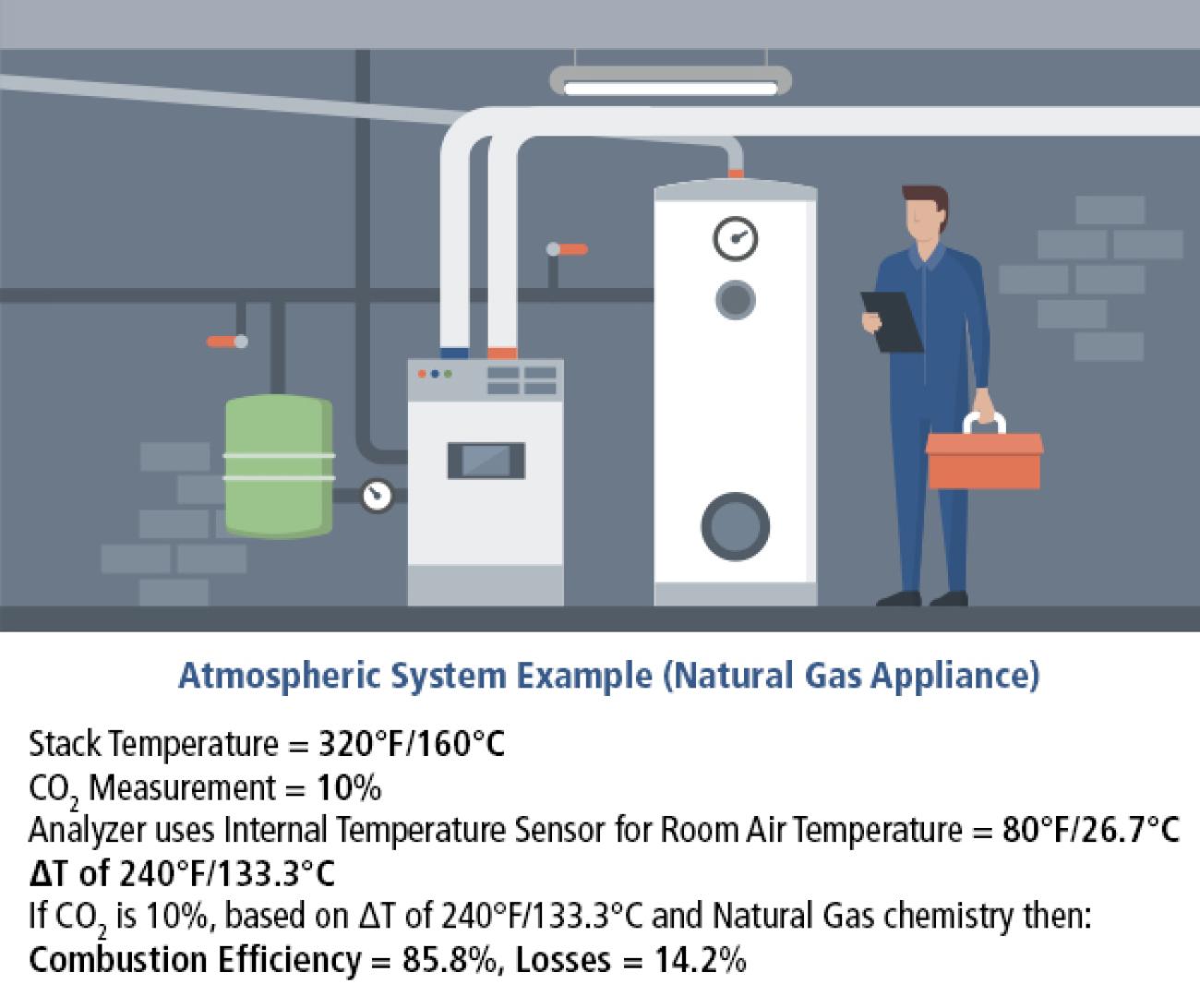

Energy efficiency is a key measure of a boiler’s performance, irrespective of the fuel it uses. Ever stricter environmental standards continue to raise the bar for combustion performance, energy efficiency and greenhouse gas emissions.

Checking whether a boiler, furnace, or other combustion equipment is properly optimised requires a modern combustion gas analyzer capable of calculating combustion efficiency. Making this calculation can be a complex task. But instruments such as the Si-CA 030, 130 and 230 analyzers, working in tandem with the dedicated Sauermann Combustion app, can deliver reliable results – all compiled into a comprehensive electronic report.

Combustion efficiency accounts for a large part of a boiler’s overall performance, alongside condensing technology and other heat recovery systems. What’s more, efficient performance helps to limit the amount of incomplete combustion residues (pollutants) released in the flue gases along with optimizing fuel savings.

Gas emissions: measuring to perfection

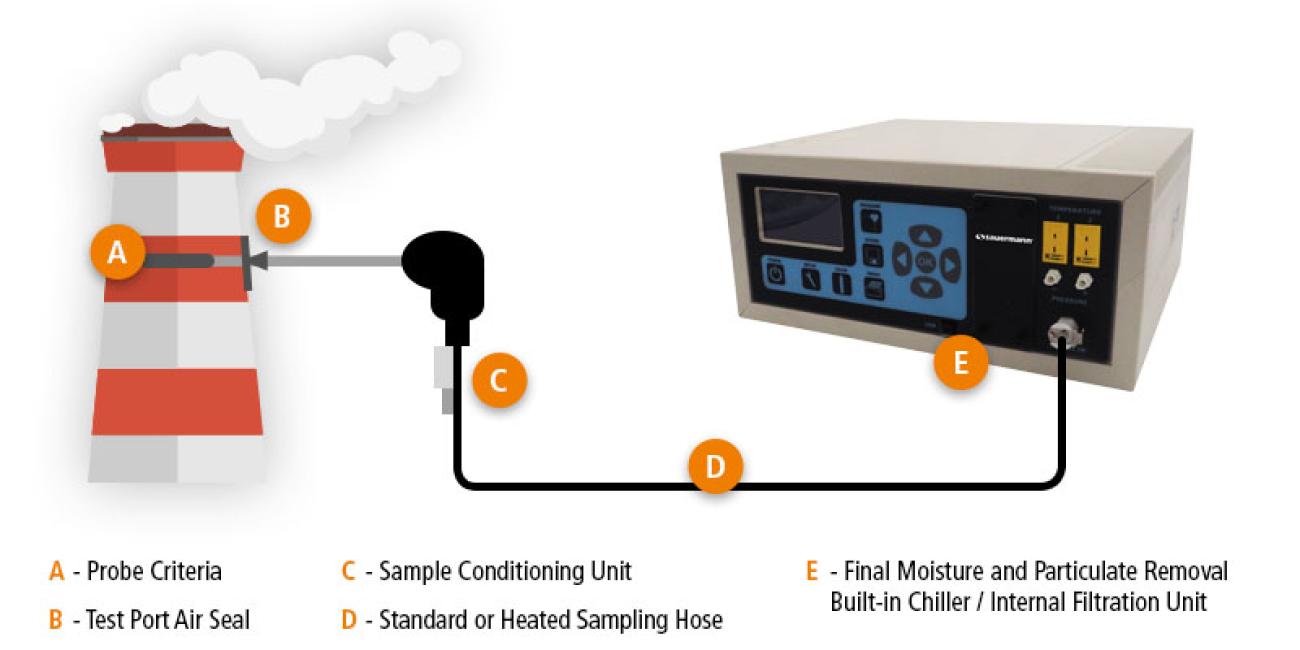

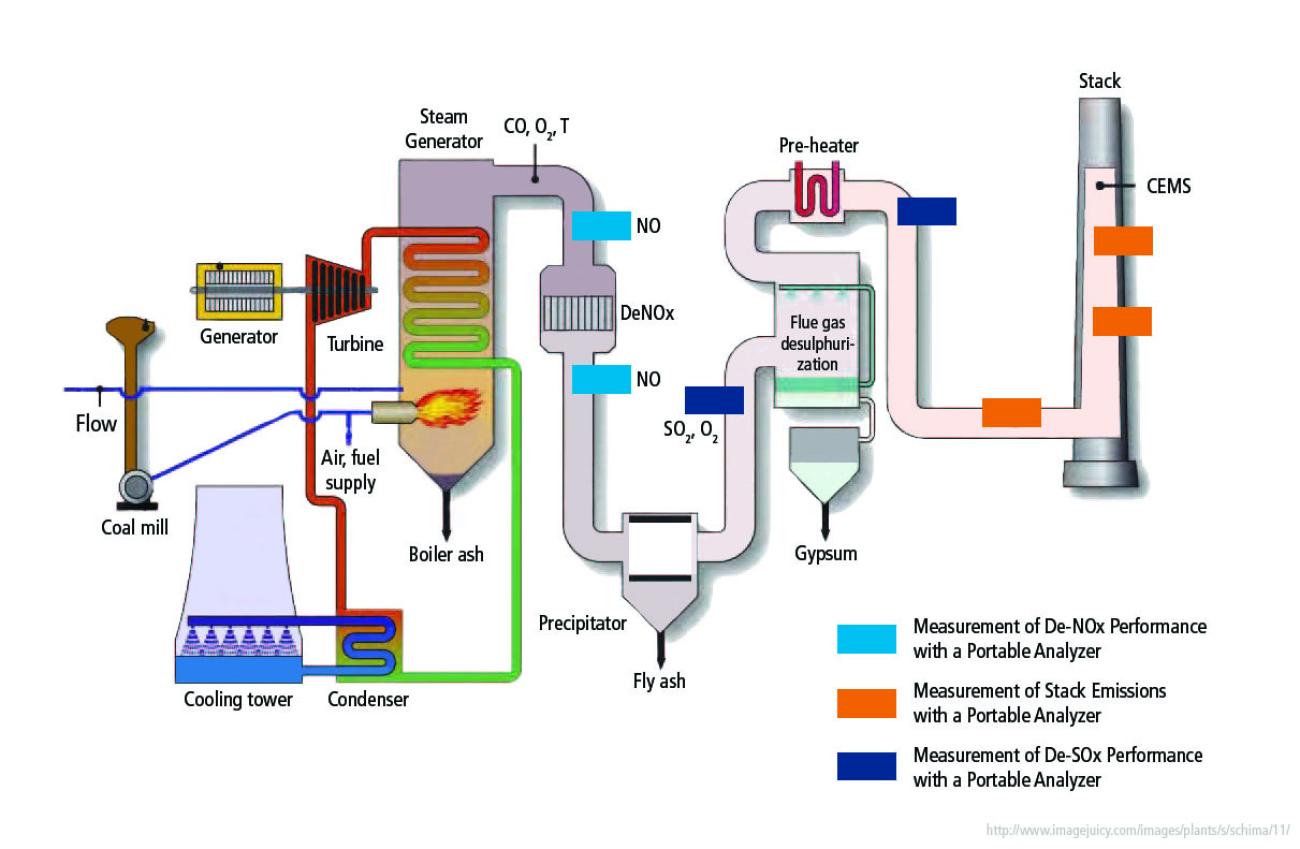

The emissions combustion equipment need to be monitored closely. But this is no easy task, since measuring emission levels requires a deep understanding of different types of combustion equipment machine, as well as how they function and what fuels they use. Combustion professionals therefore need expertise across a wide range of gases (CO, NO, NO2, SO2, CO2, HC, H2S, VOCs, O2 and more). And the method they use varies depending on the technology, power and reaction temperature of the emissions source machine in question.

In some cases, engineers will need to use accessories such as gas chillers and dehumidifiers, high-temperature probes or anti-dust pre-filters in order to avoid obtaining false measurements and to protect the instrument’s electro-chemical cells. It is important to have proper conditioning of the flue gas sampled to ensure the gases are representative of what is in the stack and optimize measurement accuracy.

The Si-CA 230 comes with a built-in dilution system for measuring high concentrations of CO (up to 50,000 ppm) while protecting the CO sensor from over-saturation that can damage the sensor. The analyzer can also calculate flue gas velocity using a Pitot tube.

Some industrial-grade boilers, engines, heaters, incinerators, & other combustion equipment require even more advanced measurement capabilities. In these cases, engineers will require a portable instrument like the Si-CA 8500, which boasts additional features such as a built-in thermoelectric gas chiller with automatic condensate removal.

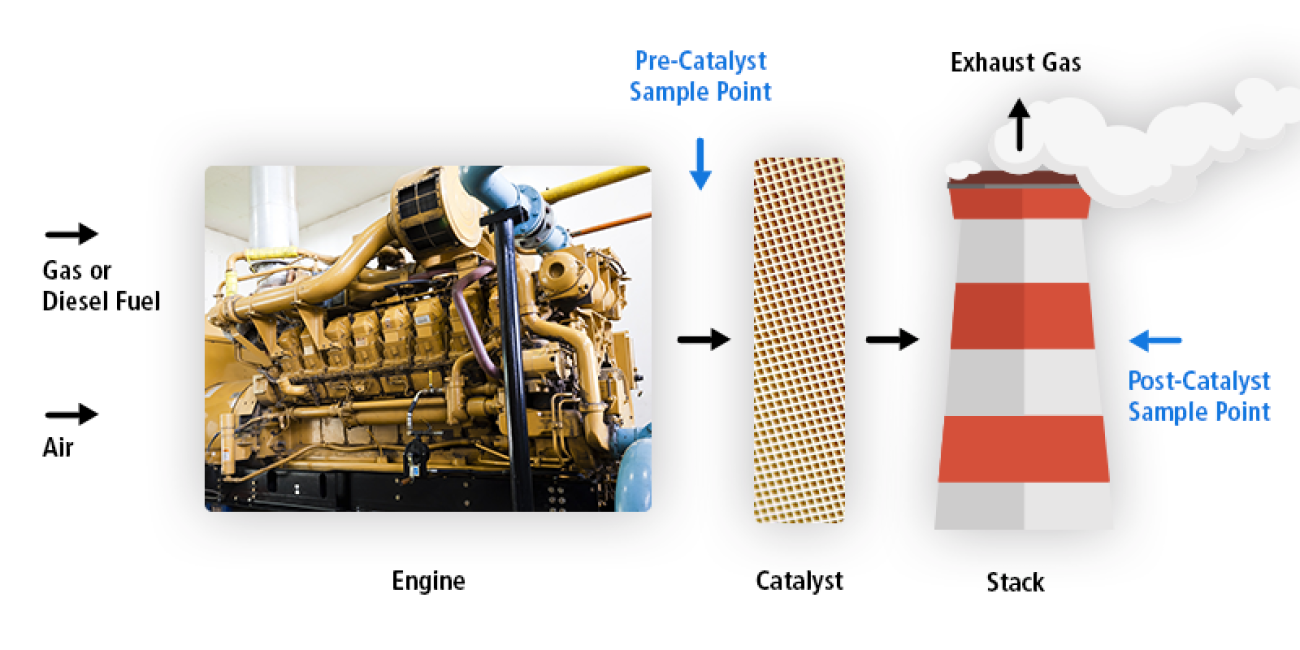

Gas and diesel engines: strict compliance and safety standards

Some combustion systems such as gas and diesel engines emit highly polluting and toxic exhaust gases, along with hydrocarbons and particulate matter. Servicing these types of engines involves taking accurate measurements to make sure they meet environmental and safety.

Once again, specialists need to monitor emissions, checking for concentrations of CO and NOx (which are highly toxic) as well as hydrocarbon residues (or CxHy), which are also toxic pollutants and which indicate incomplete combustion inside the engine (suggesting that the combustion reaction is neither fully optimised nor energy-efficient).

An analyzer such as the Si-CA 230 is highly recommended for these types of industrial machine, since it can withstand extremely high CO concentrations (up to 50,000 ppm thanks to its built-in dilution system) and is capable of measuring hydrocarbon (CxHy) residues of up to 5% upstream of the catalyst. The Si-CA 230 can also provide a Total NOx measurement with NO & NO2 sensors both pre and post catalyst.

CO, CO2, NOx, SO2, CxHy: key targets for health and the environment

As has become clear, combustion gas analysis isn’t just about measuring gas temperature, velocity and pressure. The main focus of the exercise is on specific gases – as well as on oxygen, which is an essential gas for calculating air to fuel ratio but poses no safety or pollution concerns.

Modern combustion gas analyzers like the Si-CA 030, 130 and 230, when coupled with user-selected gas sensors, are capable of measuring all the critical gases covered in this article. See this page for full details of their capabilities and features. The Si-CA 230 model can also measure hydrogen sulphide (H2S), which is a rarer but extremely toxic compound, as well as NO, NO2 and SO2 at low concentrations.

Add new comment